As a company dedicated to innovation and the provision of advanced, reliable fermentation and ultrafiltration systems, HOLVES has recently entered into a major strategic partnership with a tobacco company in North China.

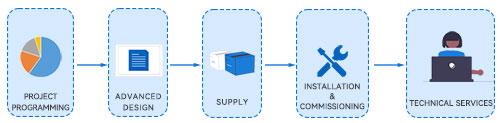

A tobacco company, as a leading supplier in the tobacco industry, chose HOLVES to provide them with advanced biotechnology fermentation and extraction combined equipment sets, not only because HOLVES products and equipment can meet their high standard needs in the field of tobacco processing, but also because HOLVES has a perfect service system. From the pre-project design, procurement to the later installation and commissioning and technical support, HOLVES provides a full range of one-stop services to ensure that customers can get a satisfactory experience in the whole cooperation process.

A tobacco company, as a leading supplier in the tobacco industry, chose HOLVES to provide them with advanced biotechnology fermentation and extraction combined equipment sets, not only because HOLVES products and equipment can meet their high standard needs in the field of tobacco processing, but also because HOLVES has a perfect service system. From the pre-project design, procurement to the later installation and commissioning and technical support, HOLVES provides a full range of one-stop services to ensure that customers can get a satisfactory experience in the whole cooperation process.

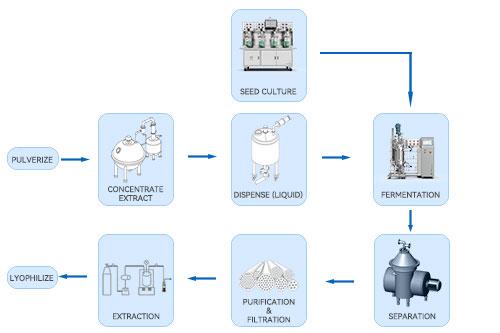

The core of this cooperation is the introduction of a series of high-end fermentation and extraction equipment produced by HOLVES, through the pre-treatment of raw materials, water extraction, filtration and concentration, membrane separation and other processes, the resulting active ingredients will be added to the tobacco. Compared with the ordinary tobacco, it has the features of moistening the throat, relieving cough and resolving phlegm.

-

Core equipment for HOLVES turnkey project

HOLVES supplied the following core equipment for this project:

Integrated Multi-Parallel Fermenter Hub240 : The Hub240 series is an integrated system designed by HOLVES for laboratory users, combining efficiency, flexibility and intelligence. The equipment is ready to use, and the glass vessels can be freely combined to meet the diverse needs of laboratory fermentation. Equipped with Siemens high-end processor with fast response and high scalability, its fast response and high scalability make the fermentation process more controllable, which helps to improve the extraction efficiency and yield of raw material active ingredients.

Automatic Series Stainless Steel Fermenter HF-AS: HF-AS series is the solution for pilot scale-up and small-scale fermentation production from HOLVES. With 10L to 2000L capacity options, the whole series of automatic sterilization technology to ensure hygiene and safety. Intelligent control system, one-button operation, automatic tank pressure and lid lifting help to maintain the stability and consistency of the extract.

Spiral Membrane Separation System : During the filtration process of the extract, the spiral membrane separation system effectively removes impurities and macromolecular particles in the extract with its high efficient filtration performance and stable filtration effect, which ensures the purity and quality of the final product.

Ceramic membrane filtration system : HOLVES ceramic membrane filtration system adopts the ceramic membrane imported from Germany OEM, which has the characteristics of high temperature resistance, corrosion resistance, good filtration performance, etc. The high-precision filtration can help to further improve the purity of the extracts, and ensure the safety and validity of the products.

In addition, it also includes ultrafine pulverizer, extraction concentrator, lyophilizer, liquid dispensing tank, disc centrifuge, multi-specification temporary storage tank, supercritical CO2 extractor, double reverse osmosis water purification system and other auxiliary equipments at each articulated end, which together constitute a complete set of bio-fermentation and extraction production line, realizing the whole process of automation and control from the raw material treatment to the final product.

Integrated Multi-Parallel Fermenter Hub240 : The Hub240 series is an integrated system designed by HOLVES for laboratory users, combining efficiency, flexibility and intelligence. The equipment is ready to use, and the glass vessels can be freely combined to meet the diverse needs of laboratory fermentation. Equipped with Siemens high-end processor with fast response and high scalability, its fast response and high scalability make the fermentation process more controllable, which helps to improve the extraction efficiency and yield of raw material active ingredients.

Automatic Series Stainless Steel Fermenter HF-AS: HF-AS series is the solution for pilot scale-up and small-scale fermentation production from HOLVES. With 10L to 2000L capacity options, the whole series of automatic sterilization technology to ensure hygiene and safety. Intelligent control system, one-button operation, automatic tank pressure and lid lifting help to maintain the stability and consistency of the extract.

Spiral Membrane Separation System : During the filtration process of the extract, the spiral membrane separation system effectively removes impurities and macromolecular particles in the extract with its high efficient filtration performance and stable filtration effect, which ensures the purity and quality of the final product.

Ceramic membrane filtration system : HOLVES ceramic membrane filtration system adopts the ceramic membrane imported from Germany OEM, which has the characteristics of high temperature resistance, corrosion resistance, good filtration performance, etc. The high-precision filtration can help to further improve the purity of the extracts, and ensure the safety and validity of the products.

In addition, it also includes ultrafine pulverizer, extraction concentrator, lyophilizer, liquid dispensing tank, disc centrifuge, multi-specification temporary storage tank, supercritical CO2 extractor, double reverse osmosis water purification system and other auxiliary equipments at each articulated end, which together constitute a complete set of bio-fermentation and extraction production line, realizing the whole process of automation and control from the raw material treatment to the final product.

-

The acceptance process

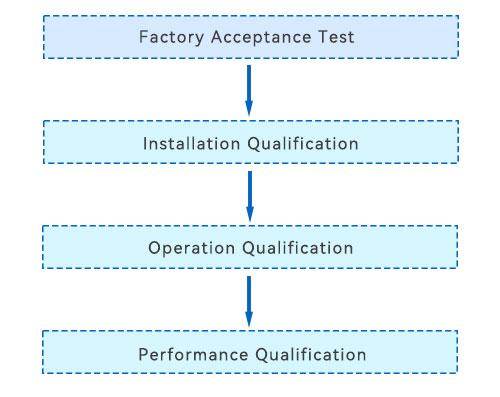

During the acceptance process, HOLVES technicians worked closely with the tobacco company's engineering team to conduct a complete validation process for each machine to ensure compliance with GMP certification standards and the multi-stage validation process required for 3Q certification.

Installation verification (IQ): This stage is to confirm that the instrument documentation, components and installation process are in compliance with the requirements. The installation process is also documented and checked in detail to ensure that all equipment is installed correctly according to the manufacturer's specifications and GMP requirements.

Operational validation (OQ): In this phase, the operational functionality of the instrument is tested, which usually involves key functions such as temperature, feed volume, autoclave, etc., to verify that the equipment will function properly within the limits of its operation.

Performance Qualification (PQ): This is the process of verifying that the instrument meets the requirements of the standard under actual sample runs. The performance of the equipment is tested under actual production conditions, including evaluation of key performance indicators such as control accuracy of the fermentation process, product yield and quality, to ensure that the equipment can achieve the expected results in actual production.

Operational training: In addition to the validation process mentioned above, HOLVES also provides comprehensive operational training services. The training includes the working principle of the equipment, operation process, routine maintenance, troubleshooting, etc., to ensure that the engineering team can skillfully master the operation and maintenance of the equipment, and improve the production efficiency and equipment life.

Operational validation (OQ): In this phase, the operational functionality of the instrument is tested, which usually involves key functions such as temperature, feed volume, autoclave, etc., to verify that the equipment will function properly within the limits of its operation.

Performance Qualification (PQ): This is the process of verifying that the instrument meets the requirements of the standard under actual sample runs. The performance of the equipment is tested under actual production conditions, including evaluation of key performance indicators such as control accuracy of the fermentation process, product yield and quality, to ensure that the equipment can achieve the expected results in actual production.

Operational training: In addition to the validation process mentioned above, HOLVES also provides comprehensive operational training services. The training includes the working principle of the equipment, operation process, routine maintenance, troubleshooting, etc., to ensure that the engineering team can skillfully master the operation and maintenance of the equipment, and improve the production efficiency and equipment life.

-

Final acceptance

After a series of tests and evaluations, the Fermentation Extraction Combined Plant Unit supplied by HOLVES successfully passed the acceptance of the tobacco company. The project solution not only meets the customer's needs, but also complies with the industry standard, providing a high-quality production solution.

HOLVES will continue to work closely with a tobacco company in North China to provide continuous technical support and services. We believe that this cooperation will help them achieve higher efficiency and better quality in the field of tobacco processing.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.

HOLVES will continue to work closely with a tobacco company in North China to provide continuous technical support and services. We believe that this cooperation will help them achieve higher efficiency and better quality in the field of tobacco processing.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.