In the long river of science and technology, material innovation is often accompanied by industrial leaps. Ceramic membrane filtration system, with its unique material and performance, is quietly leading the development of industrial separation technology.

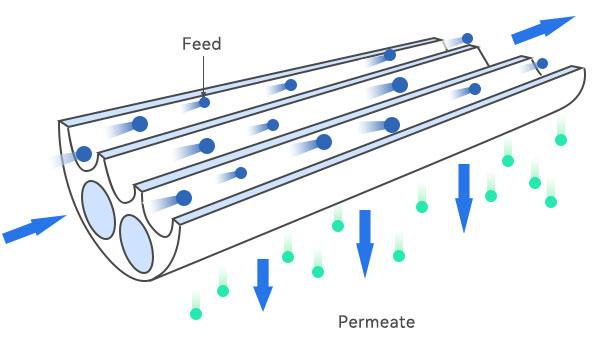

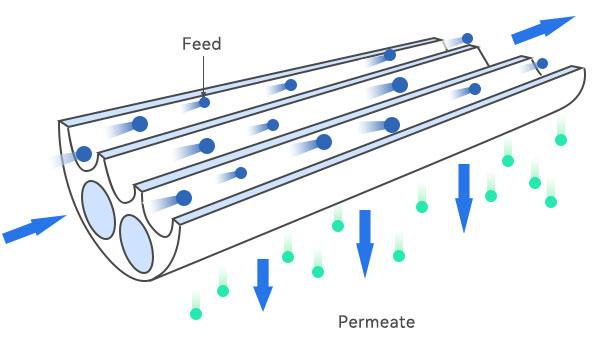

Ceramic membrane filtration is a kind of fluid separation process in the form of “cross flow filtration”: the raw material liquid flows at a high speed in the membrane tube, the clarified permeate containing small molecule components passes outward through the membrane along the direction perpendicular to it under the pressure drive, and the turbid concentrate containing large molecule components is retained by the membrane, so as to make the fluid achieve the purpose of separation, concentration and purification.

Ceramic membrane filtration is a kind of fluid separation process in the form of “cross flow filtration”: the raw material liquid flows at a high speed in the membrane tube, the clarified permeate containing small molecule components passes outward through the membrane along the direction perpendicular to it under the pressure drive, and the turbid concentrate containing large molecule components is retained by the membrane, so as to make the fluid achieve the purpose of separation, concentration and purification.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.

The meaning of ceramic membrane

Ceramic membrane filtration as a new separation technology, the core of the ceramic membrane (cartridge). Ceramic membrane, also known as inorganic ceramic membrane, is made of alumina, titanium oxide, zirconium oxide, etc. by 1700 ℃ high-temperature sintering of precision ceramic filtration materials with a porous structure, filtration accuracy covers MF, UF, NF.

Characteristics of Ceramic Membrane

Ceramic membranes exhibit distinctive characteristics. They are summarized in the following points:- Porous structure: Ceramic membrane usually has a three-layer structure, including porous support layer, transition layer and separation layer, this asymmetric distribution makes it possible to realize higher precision cutting during the separation process, so as to achieve high efficiency filtration effect.

- High Temperature Tolerance: Ceramic membranes are able to maintain their performance under extreme pH and temperature conditions up to 400°C, making them suitable for industrial processes that require high temperature treatment.

- Cleaning and regeneration: Ceramic membrane can be regenerated by chemical cleaning and physical backwashing, which has good anti-pollution ability and can prolong the service life.

Advantages of Ceramic Membrane

- Chemical Stability: Ceramic membrane is resistant to acids and alkalis, high temperatures, and even in organic solvents, which makes it comfortable in extreme environments.

- Mechanical strength: Compared with traditional materials, ceramic membrane has higher mechanical strength, can withstand greater pressure, not easy to damage, to ensure the long-term stable operation under high pressure difference working conditions.

- Anti-microbial ability: Ceramic membrane has strong resistance to microorganisms and is suitable for occasions that require hygiene protection.

- Narrow pore size distribution: the pore size distribution of ceramic membrane is uniform, high separation efficiency, and can realize finer filtration.

Application areas of ceramic membranes

Ceramic membrane filtration technology is widely used in many fields such as food industry, biopharmaceuticals, chemical industry and water treatment. In the food industry, ceramic membrane is used to clarify liquids such as fruit juice and wine to ensure the quality and taste of the products. In the field of biopharmaceuticals, it is used for the concentration and purification of biomolecules such as proteins and enzymes. In addition, in water treatment processes, ceramic membranes have demonstrated their efficient ability to remove suspended solids, bacteria and viruses. And we will continue to explore more about them afterwards, so you can look forward to that as well.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.