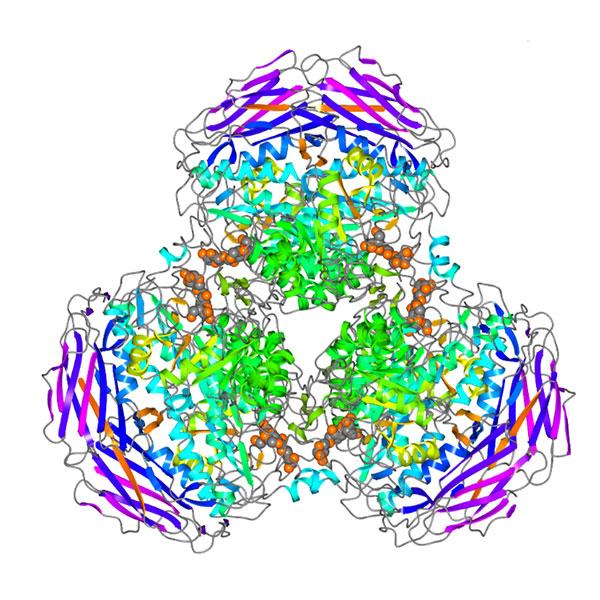

Proteins are biological macromolecules with complex structures and multiple functions. As the end product of the “central law” of biology, proteins are the main bearers of life activities. A deep understanding of the correlation between protein structure and function is the key to unlocking the “code of life” and revealing the mechanisms of all specific biological processes. Although proteins extracted from natural sources provide critical starting materials for their characterization, the scarcity of proteins and their varying quality due to sample variability pose a challenge to the field of protein biochemistry.

Thus, the concept of recombinant protein expression was born, a process in which exogenous genes encoding target proteins (POI) are introduced into the host cell via vectors and the POIs are produced by hijacking the host cell's protein manufacturing machinery. More than four decades ago, plasmids were identified as the primary messengers of exogenous genes in bacteria, thus ushering in a new era of genetic engineering and making recombinant protein expression possible.

Over the past four decades, researchers have developed a variety of vector systems as well as host cells, both prokaryotic (Escherichia coli) and eukaryotic (e.g., yeast, insect cells, and mammalian cells), to produce broad-spectrum recombinant proteins close to their natural state, facilitating biochemical research, industrial catalysis, food processing, vaccines, and therapeutics.

Thus, the concept of recombinant protein expression was born, a process in which exogenous genes encoding target proteins (POI) are introduced into the host cell via vectors and the POIs are produced by hijacking the host cell's protein manufacturing machinery. More than four decades ago, plasmids were identified as the primary messengers of exogenous genes in bacteria, thus ushering in a new era of genetic engineering and making recombinant protein expression possible.

Over the past four decades, researchers have developed a variety of vector systems as well as host cells, both prokaryotic (Escherichia coli) and eukaryotic (e.g., yeast, insect cells, and mammalian cells), to produce broad-spectrum recombinant proteins close to their natural state, facilitating biochemical research, industrial catalysis, food processing, vaccines, and therapeutics.

High quality recombinant proteins are important starting materials for research and drug development. Key attributes of recombinant protein quantities include purity, oligomeric state, thermal and chemical stability, folding, post-translational modification (PTM), activity ...... Protein expression and purification are often challenging due to the complexity of the protein itself.

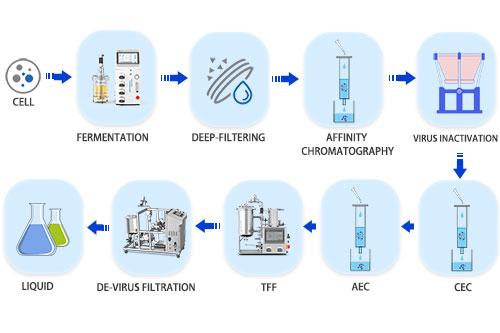

When purifying the target protein expression, unified consideration and overall design are needed, and the upstream impact on the downstream is fully considered. At the same time, different expression systems and culture methods also affect the downstream process: whether the target protein expression forms inclusion bodies or not, and the target protein expression localization (intracellular, intracellular membrane, wall membrane space and extracellular).

Recombinant protein downstream process involves membrane filtration operation units such as clarification filtration, tangential flow filtration, de-virus filtration and sterilization filtration, etc. The development of filtration processes at different stages needs to be strictly controlled.

When purifying the target protein expression, unified consideration and overall design are needed, and the upstream impact on the downstream is fully considered. At the same time, different expression systems and culture methods also affect the downstream process: whether the target protein expression forms inclusion bodies or not, and the target protein expression localization (intracellular, intracellular membrane, wall membrane space and extracellular).

Recombinant protein downstream process involves membrane filtration operation units such as clarification filtration, tangential flow filtration, de-virus filtration and sterilization filtration, etc. The development of filtration processes at different stages needs to be strictly controlled.

Compared to traditional separation techniques such as high-speed centrifuges combined with deep filtration, tangential flow technology offers a series of advantages such as high efficiency, low energy consumption, no added chemicals, and gentle operating conditions. Tangential flow filtration can be divided into microfiltration and ultrafiltration according to the pore size. Microfiltration (MF) is commonly used for fine solid-liquid separation, such as removing cell/cell debris before chromatography of recombinant proteins, yeast fermentation broths, crude extracts of plants and animals and E. coli lysates, etc., which can eliminate the traditional centrifugation and pre-filtration steps; whereas, ultrafiltration (UF) has a wider range of applications and a smaller pore size of the membranes, and it is mainly used for desalting, de-ethanolizing and concentrating recombinant proteins, endotoxins and nucleic acids. UF has a wider range of applications, with smaller pore sizes, and is mainly used for desalting, de-alcoholizing and concentrating recombinant proteins, as well as for endotoxin and nucleic acid removal. The selection of membrane pore size is extremely important, ultrafiltration membrane 1 ~ 1000kDa MWCO, microfiltration membrane 0.1 ~ 0.65 um. Selection of membrane pore size is once high, can ensure the retention yield at the same time to obtain a faster rate of transmission, which is conducive to the removal of impurities through the removal of the improvement of experimental and production efficiency, and improve the quality of products.

In the preparation of recombinant proteins,TFF technology is used in the following key steps:

In the preparation of recombinant proteins,TFF technology is used in the following key steps:

- Concentration

Recombinant proteins are often present in low concentrations during host cell culture. Tangential flow technology allows for the concentration of proteins by selecting the appropriate membrane pore size that retains the target proteins while allowing small molecules such as salts, water and metabolic wastes to pass through.

- Purification

The TFF effectively removes impurities from the culture medium and improves the purity of the recombinant protein. This step is essential to minimize potential immunogenic reactions and improve drug safety.

- Buffer exchange

Prior to further processing or storage of recombinant proteins, it may be necessary to transfer them from one buffer to another more suitable buffer. TTFF allows for this switch without loss of protein activity.

Although tangential flow technology is widely used in the concentration and separation and purification of recombinant proteins, it has some limitations. If the molecular weight difference between the two products to be separated is less than 5-fold, they cannot be separated by tangential flow.

In recombinant protein separation and purification, tangential flow technology is a widely used protein purification technology, and it is crucial to choose the appropriate membrane material, pore size, flow channel network, TMP, process flow rate, shear force and other conditions. A single one-sided choice has little effect in protein separation and purification, and it is necessary to carry out protein separation by combining protein properties and buffer systems in order to successfully scale up the developed membrane filtration process and obtain a better separation of proteins.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.

Although tangential flow technology is widely used in the concentration and separation and purification of recombinant proteins, it has some limitations. If the molecular weight difference between the two products to be separated is less than 5-fold, they cannot be separated by tangential flow.

In recombinant protein separation and purification, tangential flow technology is a widely used protein purification technology, and it is crucial to choose the appropriate membrane material, pore size, flow channel network, TMP, process flow rate, shear force and other conditions. A single one-sided choice has little effect in protein separation and purification, and it is necessary to carry out protein separation by combining protein properties and buffer systems in order to successfully scale up the developed membrane filtration process and obtain a better separation of proteins.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.