During the relentless fight against cancer, scientists have been searching for a “magic weapon” that can strike with precision and destroy those stubborn cancer cells once and for all. Antibody-drug coupling compounds (ADC) are rewriting the rules of tumor therapy, acting as well-designed biological missiles with deadly warheads that strike at the heart of tumor cells.

ABOUT ADC DRUGS

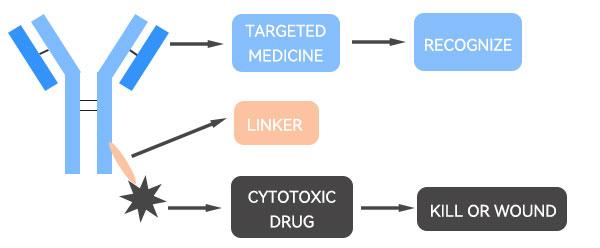

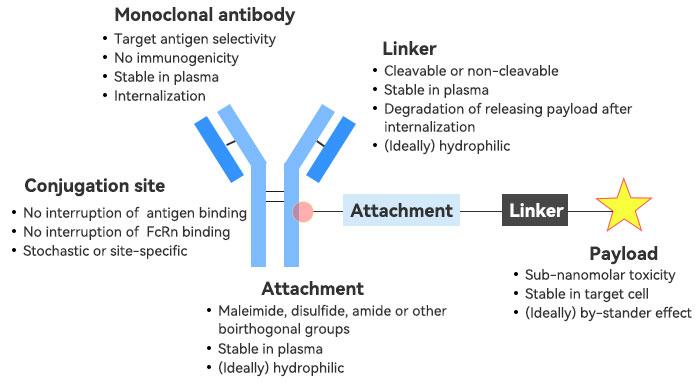

Antibody-drug coupling (ADC), a humanized or humanized monoclonal antibody coupled to a highly cytotoxic small molecule (payload) via a chemical junction, is a novel form of therapy with scope for development in cancer chemotherapy. This novel antibody-based molecular platform is capable of selectively delivering an effective cytotoxic payload to targeted cancer cells, resulting in improved efficacy, reduced systemic toxicity, and preferred pharmacokinetics (PK)/pharmacodynamics (PD) and biodistribution compared to conventional chemotherapy.

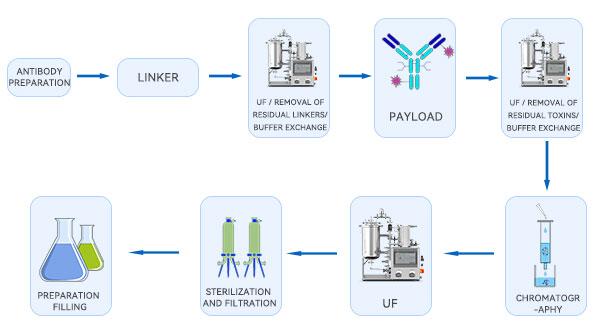

ADC drugs combine the precise targeting of biologics with the efficient killing of small molecule drugs, and thus it has become a focus of research and development as well as a new hope for human tumor therapy. Currently, TFF's UF/DF process has been widely used in ADC downstream processes to remove organic impurities, coupling-related impurities, and for buffer replacement.TFF is a simple and reliable purification method that achieves high ADC recoveries greater than 90%. In addition to the removal of small molecules (organic impurities, coupling related impurities), it is also capable of removing all drug linker related impurities, as the molecular weight of these compounds is significantly lower than the membrane pore size.

PROCESS OPTIMIZATION OF TFF TECHNOLOGY

The application of TFF technology in ADC drug preparation requires fine process optimization, including the control of inlet pressure, reflux pressure, TMP, feed flow rate, reflux flow rate, △P, filtration out of the end of the flow control, can be made according to the pressure, flux and other conditions of the automatic control of the conditions change; and can be based on the concentration of filtration factors, conductivity, pH, UV and other conditions of the automatic process switching, combined with a variety of process control can be It can realize the judgment of concentration and filtration end point. Through these key parameters to achieve the best separation effect of ADC drugs.

APPLICATION OF TFF IN ADC DRUG PREPARATION

- Concentration and desalting of antibodies: before coupling reaction, antibodies need to be concentrated and desalted.TFF can be used for concentration and desalting of ADC drug solutions to remove small molecule impurities and buffer components, and to increase the concentration of the drug in order to enhance the coupling efficiency.

- Purification of products: After coupling reaction, TFF technology can remove unreacted antibodies and small molecules of drugs by selecting filter membranes with appropriate pore sizes, as well as separating ADC from free toxins or antibodies by filter membranes with different pore sizes.

- Buffer replacement in formulation: At the stage of drug formulation, TFF technology is used to replace the buffer in the formulation to ensure the stability and activity of the drug.

Through the in-depth analysis in this paper, we can know that TFF technology is not only a process technology, but also an art of pursuing excellence in ADC drug preparation. With the development of biomedical technology, TFF technology is also being innovated and improved, which provides a solid technical support for the efficient and stable production of ADC drugs, and brings more possibilities for human beings to overcome tumor diseases.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.