Milk, one of the oldest natural dairy products. Milk is the only food for young mammals during the first stages of life. The substances in milk provide both energy and the basic nutrients needed for growth. Milk also contains many antibodies that protect young animals from infection. The process of making dairy products is rich in traditional craftsmanship and nutritional value. However, when modern technology knocks on this ancient door, the innovative technology of membrane separation is quietly changing the dairy industry. It ensures the purity and nutritional value of milk through precise separation technology, providing strong support for the safe production and quality improvement of dairy products.

Composition of milk

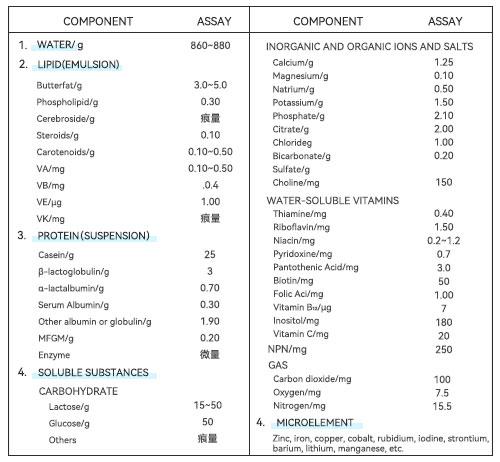

In normal milk, the content of various components is roughly stable, so people can recognize good or bad milk based on this criterion. The composition of milk is very complex, containing at least hundreds of chemical components, including water, fat, protein, lactose, salts, vitamins, enzymes and gases. When affected by various factors, its content will vary within a certain range, with fat varying the most, protein the next most, and lactose content usually changing very little. The main chemical components and basic composition of milk are shown in the table below.

As it is clear from the table, the water content is 86%-88%, protein content is 2.8%-3.3%, lipid content is 3.1%-3.6%, lactose content is 4.5%-5.0%, and there are also traces of minerals, vitamins, and so on.

Industrial use of membrane separation in the dairy industry

Membrane separation technology, which is used for the separation of molecules and ions, is a proven separation method that has been used in the dairy industry for the past several decades, as early as the early 1970s.

Today, the dairy industry in developed countries has been very common application of membrane separation technology, and continue to improve the technology to continue to expand its scope of application. In China, the application of membrane separation technology in dairy processing there is still a lot of room for development, although China's dairy industry in recent years, the rapid development of the domestic per capita consumption of dairy products is still relatively low. Membrane separation of few deep processing products, so the whole industry on a large scale application is relatively rare for the time being.

In the future, with the continuous improvement of our people's living standards, the domestic demand for dairy products is bound to increase, the quality and variety of dairy products will also put forward higher and more requirements, so the potential market for membrane separation technology in the dairy industry is very large, the industrialization of the application will be more extensive.

Today, the dairy industry in developed countries has been very common application of membrane separation technology, and continue to improve the technology to continue to expand its scope of application. In China, the application of membrane separation technology in dairy processing there is still a lot of room for development, although China's dairy industry in recent years, the rapid development of the domestic per capita consumption of dairy products is still relatively low. Membrane separation of few deep processing products, so the whole industry on a large scale application is relatively rare for the time being.

In the future, with the continuous improvement of our people's living standards, the domestic demand for dairy products is bound to increase, the quality and variety of dairy products will also put forward higher and more requirements, so the potential market for membrane separation technology in the dairy industry is very large, the industrialization of the application will be more extensive.

Membrane Separation in the Dairy Industry

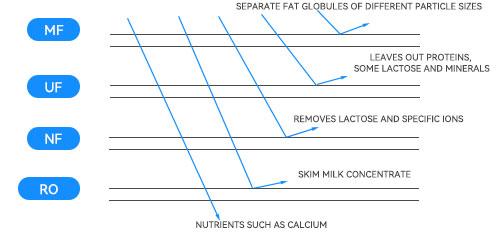

- 1. Microfiltration(MF)

It is mainly used for removing microorganisms from milk, separating and removing milk fat globules and larger suspended particles. The pore size of microfiltration membrane is usually between 0.1 and 10µm, which can effectively intercept bacteria without affecting the passage of small molecules such as lactose and minerals.

Separation of fat globules

The average particle size of fat globules in milk is 3.5µm, and fat globules of different sizes can be separated by ceramic membrane. Homogenizers can also change the particle size of the fat globules, but while homogenizers change the size of the fat globules, they also change the interfacial composition of the fat globules, i.e. they change the original natural membrane of milk fat, which consists of lactophospholipids and membrane proteins, into a membrane consisting of casein and whey proteins. The MF membrane separation technology can effectively avoid this situation,MF ceramic membrane can be in the case of not changing the interface of the fat globules, the fat globules will be divided into a variety of particle size, to meet the dairy production of stabilization and diversification.

Separation of fat globules

The average particle size of fat globules in milk is 3.5µm, and fat globules of different sizes can be separated by ceramic membrane. Homogenizers can also change the particle size of the fat globules, but while homogenizers change the size of the fat globules, they also change the interfacial composition of the fat globules, i.e. they change the original natural membrane of milk fat, which consists of lactophospholipids and membrane proteins, into a membrane consisting of casein and whey proteins. The MF membrane separation technology can effectively avoid this situation,MF ceramic membrane can be in the case of not changing the interface of the fat globules, the fat globules will be divided into a variety of particle size, to meet the dairy production of stabilization and diversification.

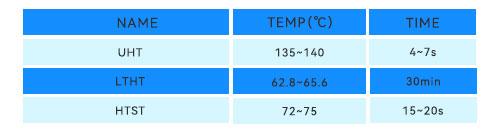

Sterilization of milk

The two most common types of sterilization used in milk processing are pasteurization and ultra-high temperature (UHT). The milk produced by ultra-high temperature sterilization is called “UHT milk”. Although UHT milk can be stored at room temperature for a longer period of time, the heat-resistant protease and lipase enzymes released by destroying the bacteria or body cells in the process of ultra-high temperature will still have a certain degree of vitality after the heating is completed, and will continue to decompose proteins and fats, resulting in a slow decline in the quality of milk. Therefore, the longer the UHT milk is stored during the shelf life, the more fresh it is, although hygienic and safe.

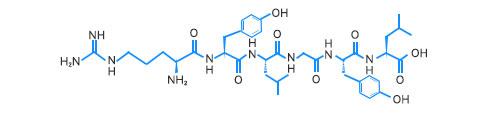

In addition, during thermal processing, lysine residues in milk proteins (β-lactoglobulin, casein, etc.) will undergo a Maillard Reaction with the carbonyl group of lactose, which generates a series of by-products that cause milk to “brown”. This not only affects the appearance of milk, but also reduces the biological value of milk proteins and amino acids, some of which (e.g., furosemide) may be potentially harmful to humans.

In terms of the content of by-products produced by heat treatment of milk, UHT milk is much higher than pasteurized milk. Therefore, pasteurized milk does have better nutritional value than UHT milk. Moreover, as ultra-high temperature heating will cause the lactoglobulin and fat globule membrane proteins in milk to produce sulfhydryl groups, and even release volatile substances such as hydrogen sulfide, it will result in UHT milk having a certain steaming flavor, while the flavor of pasteurized milk using mild heat treatment is more pure and natural.

In order to solve the problems in these two processes, the international mainstream processes include ultra-pasteurization, MF combined with thermal processing technology. Using ceramic MF membrane, using cross-flow filtration(CFF) for filtration of skimmed separated milk, and then pasteurization, the sterilization rate of milk in different tests has reached more than 99.6%, which can produce extended shelf-life milk (ESL milk) under the premise of avoiding high-temperature processing, and the shelf-life can be extended to about 20 days, and it will not degrade and destroy the nutrients in the milk.

- 2. Ultra Filtration (UF)

It is suitable for clarification and concentration of skimmed or low-fat milk with smaller pore size. Generally between 0.001 and 0.1 micron, it can intercept protein, part of lactose and minerals, while letting small molecules such as water and lactose pass through freely, so as to achieve the purpose of improving protein content and reducing water.

Separation of casein and whey proteins

Casein (CN) and whey protein (WP) in milk have significantly different processing properties and are therefore often separated in the dairy industry and used as different food processing bases. Isolated casein (CN) has good solubility, thermal and acid-base stability and is widely used in food, pharmaceutical and industrial applications. Casein is used as an additive in the food industry, as a drug delivery system in the pharmaceutical field, and as a film-forming agent in adhesives and coatings in the industrial field. Isolated whey protein (WP) is characterized by high nutritional value, easy digestion and absorption, and contains a variety of active ingredients, etc. It is recognized as one of the high-quality protein supplements for human body, and can be further produced to produce whey protein concentrate (WPC), whey protein isolate (WPI), hydrolysed whey protein (HWPI) and so on, which are used in the production of infant formulae and so on.

Separation of casein and whey proteins

Casein (CN) and whey protein (WP) in milk have significantly different processing properties and are therefore often separated in the dairy industry and used as different food processing bases. Isolated casein (CN) has good solubility, thermal and acid-base stability and is widely used in food, pharmaceutical and industrial applications. Casein is used as an additive in the food industry, as a drug delivery system in the pharmaceutical field, and as a film-forming agent in adhesives and coatings in the industrial field. Isolated whey protein (WP) is characterized by high nutritional value, easy digestion and absorption, and contains a variety of active ingredients, etc. It is recognized as one of the high-quality protein supplements for human body, and can be further produced to produce whey protein concentrate (WPC), whey protein isolate (WPI), hydrolysed whey protein (HWPI) and so on, which are used in the production of infant formulae and so on.

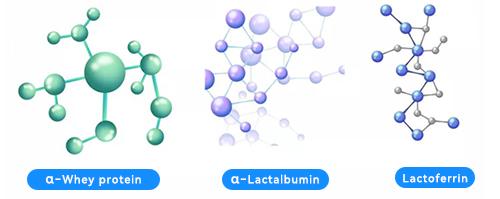

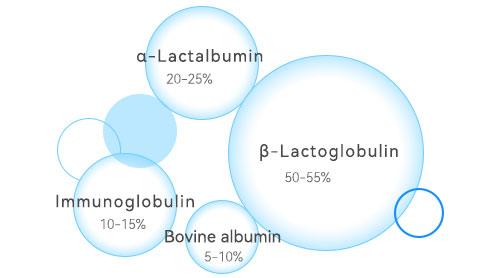

Casein in milk is mainly composed of four different caseins, namely αs1-casein, αs2-casein, β-casein and κ-casein. Each casein consists of multiple peptide chains that are interconnected by bonding to form a polypeptide chain complex with a particle size of about 110 nm. Whey protein contains β-lactoglobulin, α-lactalbumin, serum albumin, immunoglobulin, lactoferrin, lactoperoxidase and many other biologically active proteins with a particle size of about 3-8 nm, and we can select the appropriate ultrafiltration membrane to separate the two proteins according to the difference in the size of the proteins.

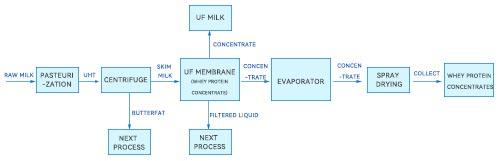

Whey Protein Concentration

Whey protein (WP) accounts for 20% of total milk protein, and vitamins and minerals in milk are also found in whey. It has high nutritional value.

Whey Protein Concentrate (WPC) is a functional milk protein ingredient that is widely used in the food processing industry, such as ham, milk cake, candy, crab stick, cake, infant formula, sports drinks, and formulated nutritional feed. Whey Protein Concentrate (WPC) enhances immune function; benefits the health of the cardiovascular system; provides functional food for breastfeeding infants and children; facilitates muscular fitness and stamina, and improves the effects of exercise; improves mental outlook, work and study efficiency; strengthens bones; facilitates optimal body weight in health care; provides high-quality proteins for people with lactose intolerance and allergies to casein and gluten; reduces skin wrinkles and photoaging, promote wound healing; prolong life.

Production of Whey Protein Concentrate (WPC) utilizes ultrafiltration technology, with the permeate containing most of the whey's lactose, minerals and water. The retentate accounts for about 1-4% of the volume of raw whey and can be spray dried to make a whey protein concentrate powder with a protein content of 35-85%, as needed.

- 3. Nanofiltration (NF)

Smaller pore size, about 0.001 micron, mainly used to remove lactose or specific ions, retain protein and minerals, suitable for the production of low-lactose or specific mineral ratio of milk products.

Concentration of raw milk

NF membrane technology has the performance advantage of selectively removing ions, and its effect is between UF and RO. In dairy production, NF membranes can be utilized to concentrate raw milk and increase the concentration of protein and fat and solids in cow's milk. In this process, the NF membrane can efficiently retain lactose and other macromolecules, while allowing part of the water and low value ions to pass through, so as to realize the effective concentration of raw milk. This type of concentration not only improves the quality of the milk, but also reduces the use of thickening agents in the subsequent processing, which is conducive to maintaining the stability of the milk structure.、

Whey Desalting

The treatment of whey is an important part of the dairy production process. Whey contains a large amount of salt and other impurities which, if left untreated, can affect the taste and quality of the final product. NF membrane technology can efficiently remove salts and impurities from whey while retaining beneficial components such as calcium ions. NF membrane technology inexpensively removes the salt taste of regular sweet whey, reduces the “saltiness” of sweet whey powders, and prepares the whey for electrodialysis and ion exchange for more complete desalination. Removes HCl and lactic acid at a lower filtration rate than lactate ions, but at a higher rate than free lactic acid molecules. It can be used for desalination of salted whey. This property has led to the use of NF membrane technology in the desalination of whey.

Improve the quality and taste of dairy products

By treating milk with NF membrane technology, harmful substances and impurities can be effectively removed, improving the safety and hygienic quality of dairy products. At the same time, NF membrane technology can also retain the flavor and nutrients in the milk, making the milk more delicious and nutritious. In addition, NF membrane technology can reduce the effect of heat treatment on proteins during production, thus further improving the quality of dairy products.

Reducing the use of food additives

During the dairy production process, it is often necessary to add some food additives in order to improve the taste and extend the shelf life of the product. However, too many food additives may affect product quality and consumer health. NF membrane technology can reduce the reliance on food additives by concentrating and purifying the beneficial components in milk, thus producing healthier, natural dairy products.

Concentration of raw milk

NF membrane technology has the performance advantage of selectively removing ions, and its effect is between UF and RO. In dairy production, NF membranes can be utilized to concentrate raw milk and increase the concentration of protein and fat and solids in cow's milk. In this process, the NF membrane can efficiently retain lactose and other macromolecules, while allowing part of the water and low value ions to pass through, so as to realize the effective concentration of raw milk. This type of concentration not only improves the quality of the milk, but also reduces the use of thickening agents in the subsequent processing, which is conducive to maintaining the stability of the milk structure.、

Whey Desalting

The treatment of whey is an important part of the dairy production process. Whey contains a large amount of salt and other impurities which, if left untreated, can affect the taste and quality of the final product. NF membrane technology can efficiently remove salts and impurities from whey while retaining beneficial components such as calcium ions. NF membrane technology inexpensively removes the salt taste of regular sweet whey, reduces the “saltiness” of sweet whey powders, and prepares the whey for electrodialysis and ion exchange for more complete desalination. Removes HCl and lactic acid at a lower filtration rate than lactate ions, but at a higher rate than free lactic acid molecules. It can be used for desalination of salted whey. This property has led to the use of NF membrane technology in the desalination of whey.

Improve the quality and taste of dairy products

By treating milk with NF membrane technology, harmful substances and impurities can be effectively removed, improving the safety and hygienic quality of dairy products. At the same time, NF membrane technology can also retain the flavor and nutrients in the milk, making the milk more delicious and nutritious. In addition, NF membrane technology can reduce the effect of heat treatment on proteins during production, thus further improving the quality of dairy products.

Reducing the use of food additives

During the dairy production process, it is often necessary to add some food additives in order to improve the taste and extend the shelf life of the product. However, too many food additives may affect product quality and consumer health. NF membrane technology can reduce the reliance on food additives by concentrating and purifying the beneficial components in milk, thus producing healthier, natural dairy products.

In summary, the application of NF technology in milk has a wide range of prospects and important value. It can not only improve the quality and taste of dairy products, but also reduce the use of food additives and production costs, injecting new vitality into the development of dairy industry.

- 4. Reverse osmosis (RO)

Has a very small pore size and is generally used for the complete purification of water. Although rarely used for milk removal, it can be used as part of a deep desalination or concentration process under certain circumstances.

At present, the concentration of milk in the domestic dairy industry usually adopts the multi-effect evaporation method, which has high energy consumption, and the longer period of high temperature heating will destroy the proteins in the milk, and will accelerate the Melad reaction. In fact, most companies use multi-stage flash evaporation method to concentrate milk, the use of higher temperatures (generally 90-120 ℃) will lead to the destruction of casein, vitamins amino acids and lactose and other nutrients in cow's milk, especially for immunoglobulin and other active substances damage, thus greatly reducing the health benefits of colostrum. The reverse osmosis membrane separation process can be used to concentrate cow's milk at room temperature or even at low temperature, which can achieve the purpose of energy saving and preventing the destruction of nutrients.

The retention rate of all nutrient components was found to be above 98% when skimmed milk concentration was utilized by RO. RO membrane has good advantages in dairy industry, the use of reverse osmosis for skimmed milk concentration can maximize the retention of calcium and other nutrients, and the product has a good thermal stability. Moreover, the growth rate of bacteria in milk concentrated by reverse osmosis is almost indistinguishable from that in raw milk, and even three of the five bacteria studied grow more slowly in concentrated milk by reverse osmosis than in raw milk.

Concentration of milk with RO membrane can significantly reduce operating costs, enhance the comprehensive utilization rate of dairy products, and the water energy consumption is much lower than the evaporation process. Membrane concentration equipment for milk is simple to operate, high degree of automation, small pollution to the environment, has a high separation efficiency, is now and will be more widely used in the future a production process.

At present, the concentration of milk in the domestic dairy industry usually adopts the multi-effect evaporation method, which has high energy consumption, and the longer period of high temperature heating will destroy the proteins in the milk, and will accelerate the Melad reaction. In fact, most companies use multi-stage flash evaporation method to concentrate milk, the use of higher temperatures (generally 90-120 ℃) will lead to the destruction of casein, vitamins amino acids and lactose and other nutrients in cow's milk, especially for immunoglobulin and other active substances damage, thus greatly reducing the health benefits of colostrum. The reverse osmosis membrane separation process can be used to concentrate cow's milk at room temperature or even at low temperature, which can achieve the purpose of energy saving and preventing the destruction of nutrients.

The retention rate of all nutrient components was found to be above 98% when skimmed milk concentration was utilized by RO. RO membrane has good advantages in dairy industry, the use of reverse osmosis for skimmed milk concentration can maximize the retention of calcium and other nutrients, and the product has a good thermal stability. Moreover, the growth rate of bacteria in milk concentrated by reverse osmosis is almost indistinguishable from that in raw milk, and even three of the five bacteria studied grow more slowly in concentrated milk by reverse osmosis than in raw milk.

Concentration of milk with RO membrane can significantly reduce operating costs, enhance the comprehensive utilization rate of dairy products, and the water energy consumption is much lower than the evaporation process. Membrane concentration equipment for milk is simple to operate, high degree of automation, small pollution to the environment, has a high separation efficiency, is now and will be more widely used in the future a production process.

Technical Advantages and Challenges

The application of membrane separation technology in the dairy industry offers multiple advantages, including improved product quality, extended shelf life, and reduced production costs. However, membrane contamination and flux decay are the main challenges facing this technology. Through continuous technological innovation and optimization of operating conditions, the anti-contamination performance and service life of membranes can be effectively improved.

As membrane separation technology continues to advance and expand its application areas, its role in the dairy industry is becoming increasingly prominent. This technology not only improves the quality and safety of products, but also promotes the modernization and transformation of the dairy industry. The application of membrane separation technology is a respect and innovation of traditional craftsmanship and a profound response to consumer health needs. Membrane separation has a wide range of applications, which HOLVES will continue to explore in the future, and you can also leave your comments in the comment section to exchange views on the future development of membrane separation and how it can better serve mankind's pursuit of health and deliciousness.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.

As membrane separation technology continues to advance and expand its application areas, its role in the dairy industry is becoming increasingly prominent. This technology not only improves the quality and safety of products, but also promotes the modernization and transformation of the dairy industry. The application of membrane separation technology is a respect and innovation of traditional craftsmanship and a profound response to consumer health needs. Membrane separation has a wide range of applications, which HOLVES will continue to explore in the future, and you can also leave your comments in the comment section to exchange views on the future development of membrane separation and how it can better serve mankind's pursuit of health and deliciousness.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.