In the modern brewing industry, ceramic membrane technology serves as a cutting-edge means of separation and purification for traditional beer and wine production. Its excellent performance not only enhances the quality and stability of the product, but also provides a strong guarantee for the sustainable development of the industry.

Applications in the beer industry

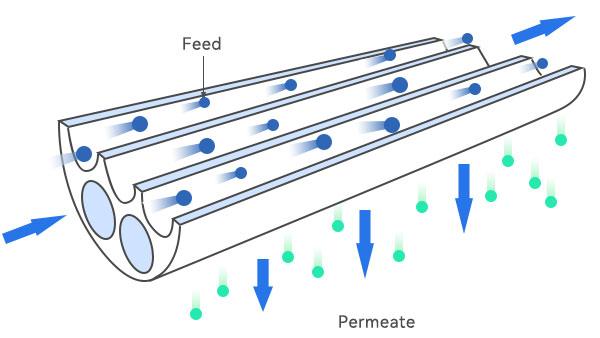

In the beer production process, TFF ceramic membrane technology is mainly used for clarification, decontamination, yeast recovery and wastewater treatment. Traditional beer filtration relies on diatomaceous earth filtration, which has many drawbacks, such as high energy consumption, limited filtration precision and loss of beer flavor. In contrast, ceramic membranes, with their high porosity, narrow pore size distribution, and good chemical stability, can efficiently remove yeast cells, suspended particles, and microorganisms from beer while retaining the flavor components.

Ceramic membranes can be used for filtration down to the microfiltration level (pore sizes ranging from 0.1-1 micron), which effectively removes yeast and suspended solids from the beer, while allowing the beneficial components of the beer to pass through. In addition, the use of ceramic membranes in beer production has significant economic advantages. Their high temperature and chemical resistance enables them to operate stably for long periods of time in more demanding environments, reducing equipment replacement frequency and maintenance costs. In beer wastewater treatment, ceramic nanofiltration membrane technology can efficiently remove organic matter and suspended solids from wastewater, reduce chemical oxygen demand (COD) and biochemical oxygen demand (BOD), and at the same time, recover some of the useful components, such as sugars and amino acids.

Applications in the wine industry

In the wine industry, ceramic membrane technology also shines. Traditional wine clarification processes rely on centrifugation and diatomaceous earth filtration, which can be time-consuming and result in loss of flavor. Ceramic membrane technology offers a gentler and more efficient alternative. The microporous structure of ceramic membranes accurately removes impurities such as suspended particles, yeast, pectin and large proteins from wine, while retaining the maximum amount of aroma and flavor. After a winery in Bordeaux, France, adopted the ceramic membrane system, the clarification time of the wine was shortened from 72 hours to 4 hours, and the wine was more full-bodied and fruity. At the same time, the active components of the wine, such as alcohols, acids and dry leachates, are retained.

In addition, ceramic membranes play an important role in wine micro-oxygenation. Through the microporous structure of the ceramic membrane, oxygen can be dispersed slowly and evenly into the wine, promoting the oxidation of phenolic substances while avoiding over-oxidation. This precise control of oxygen helps to enhance the flavor and quality of the wine, making it more full-bodied and layered.

In addition, ceramic membranes play an important role in wine micro-oxygenation. Through the microporous structure of the ceramic membrane, oxygen can be dispersed slowly and evenly into the wine, promoting the oxidation of phenolic substances while avoiding over-oxidation. This precise control of oxygen helps to enhance the flavor and quality of the wine, making it more full-bodied and layered.

Comprehensive Advantages and Future Prospects

The continuous progress of ceramic membrane filter technology makes the application prospect in the field of wine brewing more broad. The research and development of new nano-ceramic membrane materials will further enhance the filtration precision and flux; the introduction of intelligent control systems will make the production process more precise and controllable. These technological advances are driving the wine brewing industry in the direction of greater efficiency, environmental protection and intelligence.

The application of ceramic membrane technology is not only a technological innovation, but also the inheritance and sublimation of traditional brewing technology. It guards the quality of liquor products with the power of science and technology, bringing consumers a purer taste experience. In the future production of liquor, ceramic membrane technology will certainly play a more important role in promoting the whole industry to a new height.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.