Ceramic Membrane System

-

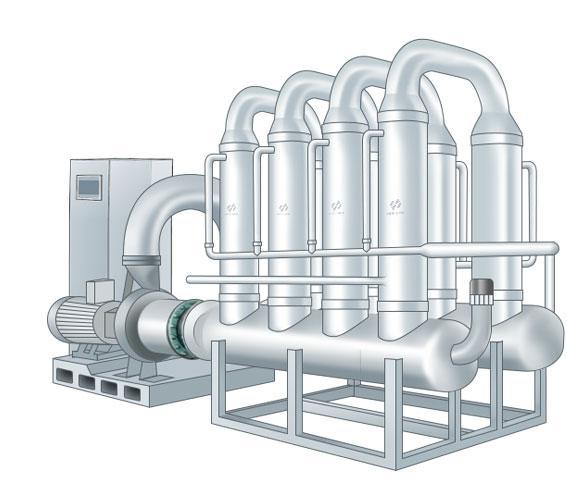

As the market demand increases, the design of ceramic membrane filtration systems also tends to be high-end. After the experience of designing tangential flow ultrafiltration systems, HOLVES has reorganized and redesigned a new generation of ceramic membrane filtration systems, the K₂C series ceramic membrane filtration systems, in order to respond to the design requirements of an increasing number of food and pharmaceutical users.

-

The design and development of the K₂C series ceramic membrane filtration system has made significant progress in automation by drawing on the successful experience of the TFF system, while the introduction of the sanitary filtration design ensures that the system meets the hygienic requirements of food and pharmaceuticals, thus further improving the filtration efficiency and separation effect. In the selection of membrane consumables, atech ceramic membranes of German origin are used to ensure the filtration effect and high precision of the system in use.

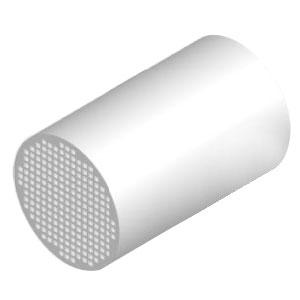

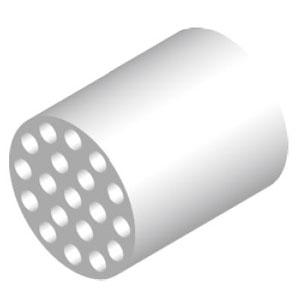

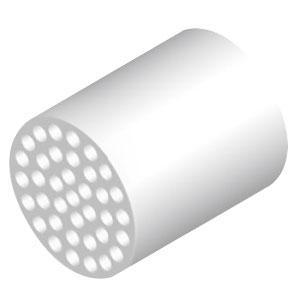

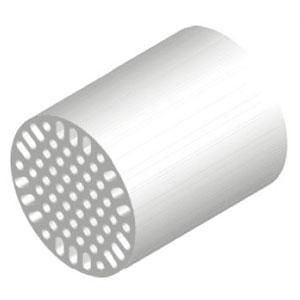

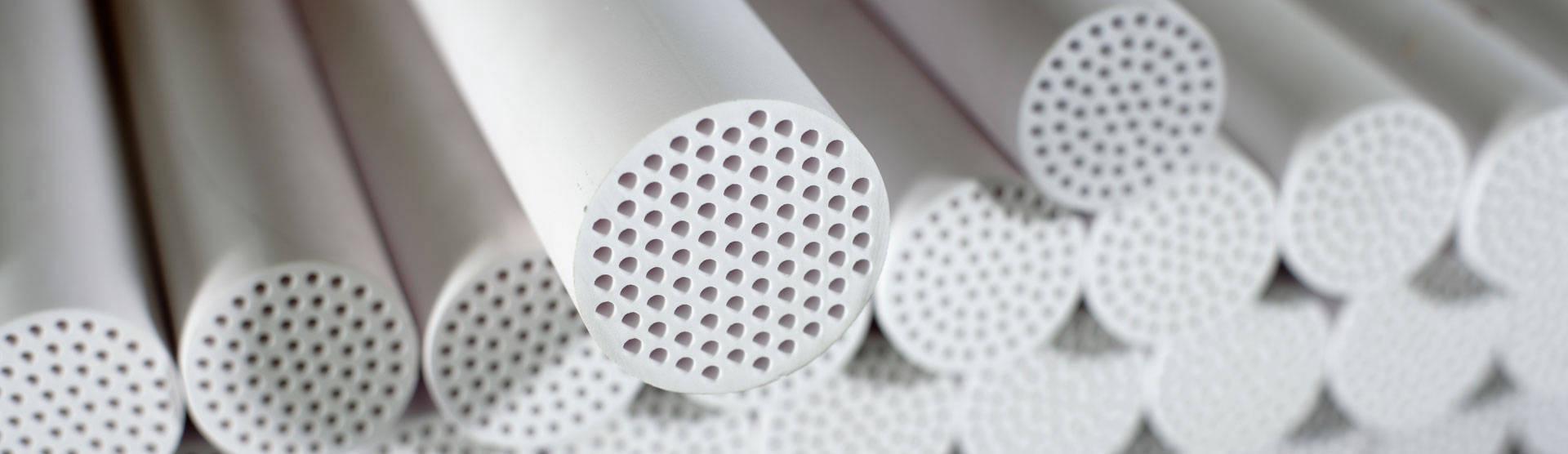

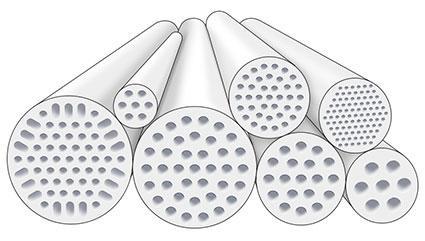

Germany Atech Ceramic Membrane

ATECH ceramic membrane is the best choice for fine ultrafiltration. As the authorized partner of ATECH in China, HOLVES is committed to promoting German high-quality ceramic membranes to the domestic market and providing users with more efficient and stable ceramic membranes. It is also the guarantee premise that HOLVES ceramic membrane filtration system can realize precise design and stable operation.

HOLVES has worked with ATECH for many years and has accumulated a wealth of practical experience. With deep understanding and innovation in ceramic membrane technology, HOLVES stands out in the design and application of filtration systems, ensuring efficient and reliable solutions for users to meet the stringent needs of different industries.

- 3A Sanitary Certification and SMW Certification

Compliant with EU 8/ISO/IEC and 2005/31/ICC (9352/2004/ICC) regulations regarding ceramic materials in contact with food.

- Quality, Diversity and Functionality

For every application in the field of liquid-liquid and solid-liquid filtration, atech offers the right ceramic membrane. These products are not only impressive for their high purity, but also for their large number of membrane designs and different membrane pores.

- Personalized advice and top service

atech ceramic membranes offer personalized advice to users. Qualified staff with many years of experience are on hand at all times. Extreme flexibility and the shortest possible delivery times as well as excellent after-sales service are atech's strengths.

- Reliability, Durability and Sustainability

The high quality of atech membranes and their chemical, thermal and mechanical stability ensure operational reliability and durability. atech is committed to environmental protection and sustainability. Using its ceramic membranes, factories can operate for more than a decade without any problems in membrane function.

Characteristics of atech membranes

- Excellent chemical stability (pH 0 to 14, acids, bases, oxidizers, etc., even at high temperatures)

- Mechanical strength (high backwash pressure, high TMP, erosion, etc.)

- High temperature resistance, can be steam sterilized

- Service life up to 10 years or more

- High operational reliability

- Chemically inert

- Cleaning is easier and faster

Advantages of atech membranes

- High purity materials, no mixtures

- No adhesives

- High sintering temperature (1700-1800°C), high burst pressure and high corrosion resistance

- Stable product quality, especially for high-precision ultrafiltration membranes

- Membrane layers made of Al₂O₃, TiO₂ and ZrO₂

- Ensures constant high quality through an extended quality control program

Atech Ceramic Film Selection

- Molecular weight range down to 1KD

- Available in standard 1178mm and 500mm lengths, customized lengths up to 1500mm are available

| Filtration Range | MF | UF | NF |

| Membrane Pore Size / MWCO |

1.2μm 0.8μm 0.4μm 0.2μm 0.1μm 0.05μm |

150KD 100KD 25KD 15KD 5KD 1KD |

750D 450D 200D |

| Separation Layer Material |

α-Al₂O₃ ZrO₂ TiO₂ |

TiO₂ ZrO₂ Al₂O₃ |

TiO₂ |

| Operating Pressure | 0-5bar | 3-8bar | 8-15bar |

Sanitary System Design

Traditional ceramic membrane filtration designs have evolved from water treatment, and as a result, a large number of non-sanitary designs have proliferated throughout the ceramic membrane filtration system industry. Due to the success of the HOLVES TFF products, the HOLVES K₂C series of ceramic membrane systems draws heavily on sanitary system designs, allowing the K₂C series of ceramic membrane systems to be used in a wide range of applications in the food and pharmaceutical industries.

- 3A Sanitary Standards: Adopting 3A sanitary standards for design, strictly enforcing the use of materials and welding.

- 3D Design: The piping is designed in sanitary 3D to avoid residue, stagnant fluids, emptying and maintenance issues.

- Seamless Welding: Seamless welding technology is used for key piping to ensure no dead ends or rust problems.

- Selected Components: Valves, piping, sensors are of sanitary design and branded components.

- Fully-automatic Control: Reduce human intervention and ensure product consistency with a high degree of automation.

HSeal Sealing Technology

EPDM / PTFE / PP

As one of the core components of the ceramic membrane filtration system, the membrane shell plays a crucial role. HOLVES membrane shell adopts the imported flat replacement program, cooperates with domestic industry leading manufacturers, and integrates the self-developed HSeal sealing technology, which is a perfect replacement for the imported membrane shell.

- Sealing Solutions: Divided into single seal and integral seal types

- Sanitary Requirement: The overall design and implementation of strict compliance with ASME-BPE design and health requirements.

- Technology Characteristics: The application of this technology ensures system integrity and low leakage, which is critical to maintaining the long-term reliability and stability of the filtration process.

Product Applications

Pharmaceutical

Desalination of antibiotic resin analysis solution, concentration of vitamins

Food

Fractionation and purification of oligosaccharides and starch sugars

Extract

Clarification and filtration of plant and animal extracts

Condiment

Sterilization, clarification and filtration of soy sauce, vinegar, etc.

Dyes

Desalination and concentration instead of salting and acid precipitation

Recycling mother liquor

Removal of impurities from MSG mother liquor, removal of impurities from glucose crystal mother liquor

Dairy

Sterilization of skimmed milk, separation of milk, fat, recovery of whey protein, etc.

Beer/Wine

Filtration and clarification in beer and wine production

Depyrogenated water

Ensure that any remaining particles, bacteria or endotoxins in the water for injection are safely removed

Chinese medicine

Clarification, removal of impurities and filtration of aqueous extracts of Chinese herbal medicines

Discover Our Products

CS320 Desktop Ceramic Membrane Filtration System

CS350 Pilot Ceramic Membrane Filtration System

CS380 Product Ceramic Membrane Filtration System

Ceramic Membrane Scale-up Process

Holves' ceramic membrane filtration systems are designed from the outset with scale-up production in mind, ensuring a seamless transition from laboratory scale to industrial scale. Through the following strategies, HOLVES is able to offer customers an efficient, reliable and cost-effective solution for the scale-up of their ceramic membrane filtration systems.

- Modular and standardized design: HOLVES ceramic membrane filtration system adopts modular and standardized design, which allows customers to flexibly increase the membrane components and treatment capacity according to the production demand, and realize the maximization of cost-effectiveness and simplicity of operation.

- Advanced automation and control system: With the increase of production scale, the automation and control system equipped with the system will be upgraded to realize more efficient production management and precise process control to ensure the consistency and reliability of product quality.

- Membrane material and process optimization: The use of high-purity ceramic membranes imported from Germany ensures high temperature resistance, chemical stability and mechanical strength under a variety of scale-up production conditions, ensuring that the best filtration efficiency and product quality are maintained in the scale-up production.

- Environmental and Safety Compliance: Following 3A sanitary standards and ASME-BPE design requirements, our systems are designed to meet the strict sanitary and safety requirements of the food and pharmaceutical industries. Reduce environmental impact and ensure operator safety for a sustainable manufacturing process.

- Application of ceramic membrane filtration: The system design takes into account a wide range of application scenarios, whether in pharmaceuticals, food processing, clarification of extracts or other industrial applications, it is able to provide customized solutions for scale-up production.

Product Brochure

HOLVES offers advanced pharmaceutical grade tangential flow ultrafiltration systems and is dedicated to the development and production of automated systems. The product line ranges from small scale research to large scale production automation systems for a wide range of applications in biopharmaceuticals, synthetic biology and chemical pharmaceuticals.