About Microcarrier

-

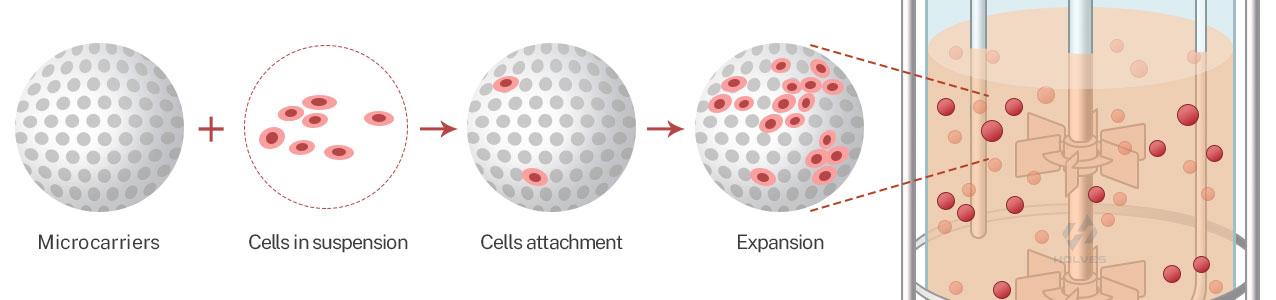

Microcarrier (Microcarrier) means a class of microspherical scaffolds with a diameter of 50-350 μm and a density slightly higher than that of water, which have biological functions such as cell culture, proliferation and delivery. During the process of cell value-added differentiation, it can adhere to cells and provide a support matrix for cells.

-

HOLVES develops and produces a wide range of cell culture carriers, including not only dextran-based microcarriers (HCD-001 and HCD-003), but also biodegradable gelatin 3D carriers (H3C-001 and HSD-001) and polyester fiber carriers (HCF-001 and HCSD-001) to meet the user's individual needs in the cell culture and purification process, and to facilitate the innovative development of the biopharmaceutical industry.

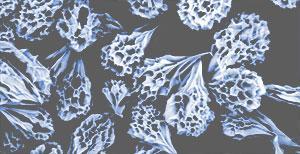

Microcarriers of different materials

The most common classification of microcarriers is based on materials, including dextran microcarriers, gelatin microcarriers, cellulose microcarriers, polystyrene microcarriers, chitosan microcarriers, polyurethane foam microcarriers, alginate gel microcarriers, magnetic microcarriers and other microcarriers. And because these raw materials can be formed into a variety of different shapes, and can be classified according to the shape of the common spherical, flaky, fibrous, tubular, microporous and so on.

- Dextran microcarriers: Almost all animal cells that can be adhered to the wall in vitro can adhere to these microcarriers.

- Gelatin microcarriers: suitable for wall-dependent cells and suspension culture cells, such as human bone marrow mesenchymal stem cells.

- Cellulose microcarriers: suitable for wall-dependent cells and suspension culture cells. Mainly used for the production of recombinant products and monoclonal antibodies by culturing CHO, BHK, NSO and hybridoma cells.

- Polystyrene microcarriers: more applied in fluidized bed perfusion culture of CHO cells, also can be used to culture adherent and semi-adherent cells.

- Polyester fiber microcarriers: carriers for mammalian cell monolayer culture.

There are also polyurethane foam microcarriers, alginate gel microcarriers, magnetic microcarriers, etc. These microcarriers play an important role in the field of biotechnology due to their different physical and chemical properties, which can support the attachment and growth of different types of cells. When selecting microcarriers, comprehensive consideration should be made based on specific cell types, culture conditions, and costs.

HCD-003 Spherical Microcarrier(HCD-003G)

HCD-003 is a multifunctional microcarrier designed to promote the adherent growth of multiple cell types. The core structure of the product is a dextran microsphere with a layer of non-animal derived recombinant collagen affixed to its surface. This unique surface modification gives HCD-003 special advantages in vitro culture techniques, especially under serum-free conditions, and provides a more efficient mass culture environment for difficult-to-cultivate cell types such as bone marrow and embryonic MSCs cells, Vero cells, MRC-5 cells, and 2BS cells.

After sterilized by gamma rays, HCD-003G microcarriers are loaded into PC vessels equipped with dedicated carrier transfer tubes to ensure the sterility of the carriers to meet the requirements of high-standard biological laboratories. We offer customization services to adjust the loading capacity of the carriers to suit the specific needs of different customers.

- The surface-covered recombinant collagen has the characteristic of being easily hydrolyzed. It not only optimizes the cell harvesting process, but also helps to protect cell viability and function, while keeping the integrity of the cell membrane and to promote the scale-up of continuous cell culture.

- The large specific surface area allows more cells to be cultured per unit volume of culture solution, increasing cell yield.

- Allows cell culture to be achieved in a variety of bioreactor systems, including scale-up stirred bioreactors, single-use bioreactors, and shake flasks.

- Achieve efficient separation technology that makes it easy to separate cultures and cells from the medium and thus collect the products, and support the operation of perfusion culture or fed-batch culture.

- Supports the process of scaling up cell cultures, which involves either digesting cells from an existing carrier and re-inoculating them into a new carrier, or scaling up the culture by directly feeding the cells into a new carrier.

H3C-001 Gelatin 3D Microcarrier

H3C-001 Gelatin 3D microcarrier are made through several fine processes, with an effective culture area of up to 9000cm²/g, a dry powder particle size distribution of 150 to 300 μm, and an internal structure containing large pores ranging from 20 to 50 μm, which provides a stable micro-environment for adherent cell growth.

Due to the natural biocompatibility of gelatin, H3C-001 microcarriers are not only suitable for high-density culture of conventional cells, but also for cell types that are difficult to grow against the wall, making them a versatile and efficient choice for cell culture.

- Gelatin is biocompatible, porous, non-rigid, non-toxic, active, easily degradable and recyclable. The large specific surface area can meet the large-scale culture of mammalian cells, and it has a good bearing effect for both adherent and suspension culture cells.

- Its unique 3D structure increases the culture surface area, which can provide more adhesion sites and growth space for the cells, and can enable the cells to obtain a relatively stable growth environment inside the carrier, reducing the influence of external factors on the cells.

- The H3C-001 carrier was able to achieve more than twice the cell density of conventional dextran microcarriers in MSCs cell culture.

- Made of medical grade gelatin material. It can be gradually degraded in living organisms or in specific environments, and its degradation products are usually small molecules such as some non-toxic amino acids, which can be metabolized and absorbed by living organisms, thus realizing highly efficient cellular recycling with a recycling rate of more than 90%.

- A wide range of applications, not only in the field of cell therapy, but also in the fields of exosome preparation, biopharmaceuticals, animal vaccine production, and cultured meat, can be realized in bioreactors for large-scale culture.

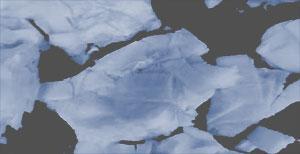

HSD-001 Gelatin 3D Sheet Microcarrier

HSD-001 is an innovative sheet microcarrier made from medical grade gelatin. It consists of multiple layers of sheets stacked on top of each other and can be rapidly dispersed into individual sheets in culture medium or PBS buffer. Each sheet is diamond or rectangular in shape, larger than 5mm in size, and has an internal macroporous structure of 10-100μm, providing a stable and suitable microenvironment for cell growth.

In fixed-bed bioreactors, HSD-001 performs well in applications that can effectively support the expansion of cell seed vessels and the efficient expression of products in terminal culture vessels. Whether used for cell culture or product expression in WAVE bioreactors, HSD-001 Gelatin 3D Sheet Carrier demonstrated excellent performance.

- Diamond or rectangular in shape, with a length of more than 5 mm on one side, they can be rapidly dispersed into individual sheets in culture medium or PBS buffer, and are suitable for large-scale culture in fixed-bed bioreactors.

- Degradable by trypsin, recombinant collagenase and collagenase, they ensure high cell recovery rates, typically up to 90% or more.

- With an internal porous structure of 10-100 μm, the larger specific surface area is capable of achieving cell densities more than 2 times higher than traditional dextran microcarriers in the culture of MSCs cells.

- Suitable for fixed-bed bioreactors, WAVE bioreactors and other bioreactors to meet the needs of different situations.

- With natural affinity to cells, it is more suitable for high-density culture of various adherent cell types that require higher growth environment, such as MSCs, MRC-5, 2BS and WI-38 cells.

Carrier Info

| Name | Type | Size | Number | Postscript |

|

HCD-003 Spherical Microcarriers |

HCD-003 HCD-003 HCD-003 HCD-003 |

25g 50g 250g 1000g |

HCD003-001 HCD003-002 HCD003-003 HCD003-004 |

|

|

HCD-003G Spherical Microcarriers Microcarriers are gamma sterilized |

HCD-003G HCD-003G HCD-003G |

150g 600g 3000g |

HCD003G-001 HCD003G-002 HCD003G-003 |

Microcarriers are gamma sterilized. They are sterilized before being put into the preparation process, so the user does not need to perform additional cleaning or autoclaving steps. Customized loads are available upon request. |

|

H3C-001 Gelatin 3D Microcarriers |

H3C-001 H3C-001 H3C-001 H3C-001 |

1g 5g 10g 100g |

H3C001-001 H3C001-002 H3C001-003 H3C001-004 |

|

|

HSD-001 Gelatin 3D Sheet Microcarriers |

HSD-001 HSD-001 HSD-001 HSD-001 |

1g 5g 10g 100g |

HSD001-001 HSD001-002 HSD001-003 HSD001-004 |

|