Bio Intelligent Pump

-

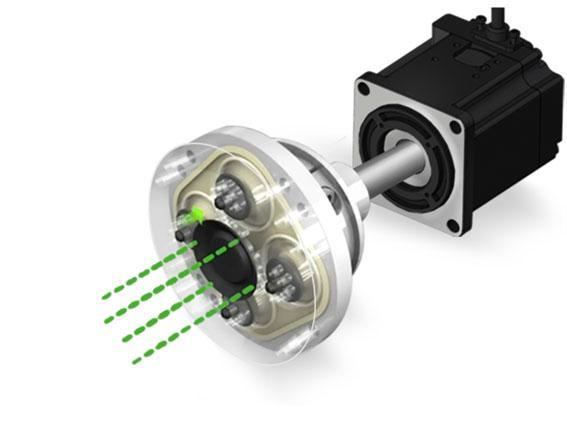

The newly developed K₂P series of intelligent pumps from HOLVES uses four-piston diaphragm pump as the power system, which has the characteristics of low shear and low pulsation. This series of intelligent pumps has built-in K₂P-Control filtration software, which eliminates the need for complex additional installation and deployment operations, and can greatly simplify the experimental and production process and improve work efficiency.

-

HOLVES has been focusing on creating high-quality fluid solutions for users in the field of biopharmaceuticals and providing comprehensive and high-quality product support services to meet the industry's development needs.

Soft Delivery, Low Pulse, Low Shear

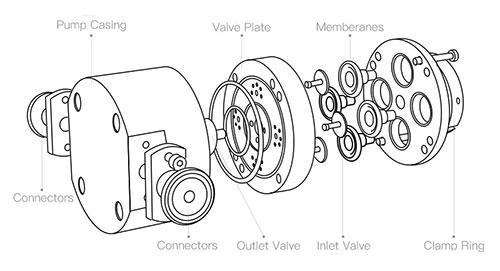

The diaphragm pump works like a mammal's heart, with the diaphragm and the inlet and outlet check valves working together to create a continuous flow and pressure. This series of intelligent pump uses elastic check valve and diaphragm, and the flow channel inside the pump is designed with smooth rounded corners to minimize the sharp shapes inside the flow channels. In addition, there are no parts in the pump that are prone to wear and heat generation, allowing gentle, safe and stable pumping of shear-sensitive aqueous solutions and biological products, minimizing the impact on the product.

- Adopts elastic check valves and diaphragms, designed with smooth rounded flow channels to minimize sharp shapes.

- There are no parts in the pump that are prone to wear and heat generation, safer and more stable.

- The diaphragm pump can deliver softly ,minimizing the impact on the product.

Sanitary Design, Safe and Efficient

The unique flow channel structure ensures that the pump head, especially the diaphragm chamber, can be completely emptied of liquid at the end of the work without any accumulation of liquid. The metal parts are made of SS316L stainless steel, and the surfaces in contact with liquid are machine polished and electropolished so that the surface roughness is Ra<0.4um, and meets the standard requirements of ASME BPE. All non-metallic bodies in contact with liquids (diaphragms, check valves, seals, etc.) are made of FDA and USP Class VI compliant materials to ensure material safety and to meet the stringent pharmaceutical grade requirements.

The meticulous design gives the product a lively life

- The pump body adopts a four piston diaphragm pump design, with no mechanical seal or liquid-connected rotating parts, ensuring the overall sealing of the product;

- High-grade matte surface of the shell, snap-on design, simple and aesthetic;

- The rich electrical interfaces support plug-and-play functionality,easily manage various traffic tasks;

- 4.3 / 7 inch HMI color touch screen, more intuitive function parameters, experimental operation, to enhance the user's sense of use.

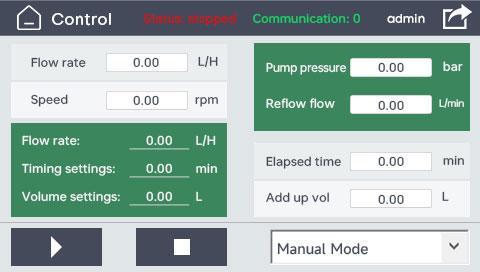

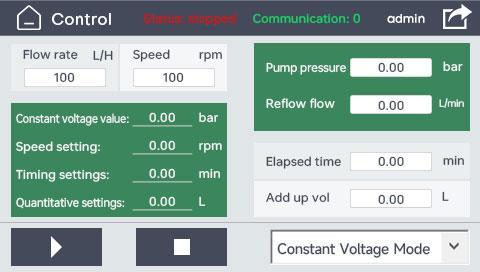

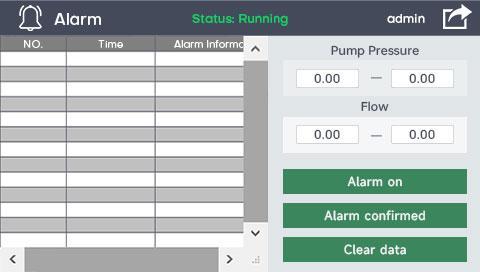

Intelligent operating system, from complexity to simplicity

- The product is built-in with the new generation K₂P-Control software system, which brings industrial-grade human-machine interaction experience;

- By configuring accessories such as pressure sensors and flow meters, it is possible to realize constant current and constant pressure;

- Dispensing function for delivering fluids at regular time and quantity;

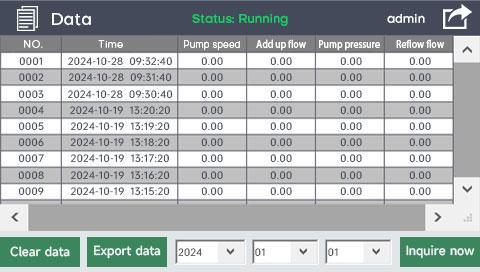

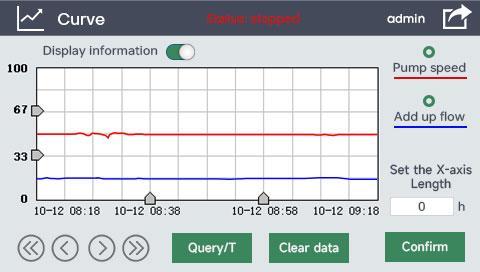

- With data recording, curve analysis, alarm setting, audit trail and many other function modules.

K₂P-Serics Intelligent Pump

| Mode | K₂P-60 | K₂P-180 | K₂P-1200 | K₂P-2500 | K₂P-5500 |

| Flow rate (L/H) | 60 | 180 | 1200 | 2500 | 5500 |

| Flow rate accuracy | ±2% | ±2% | ±2% | ±2% | ±2% |

| Maximum pressure resistance | Medium temperature ≤40℃: 6bar; Medium temperature >40℃: 4bar | ||||

| Connection size | 1/4”TC | 1/4”TC / 1/2”TC | 3/4”TC | 1”TC | 1.5”TC |

| CIP/SIP | 0.1-1M NaOH,121℃ SIP | ||||

| Pump material | Pump chamber:SS316L; Diaphragm Material:TPE; Sealing material:EPDM | ||||

| Shell material | Matte stainless steel no fingerprints process | ||||

| Software version | K₂P-Control V1.0 | ||||

| Power (KW) | 0.2 | 0.2 | 0.9 | 2.0 | 4.0 |

Application

TFF

Deep filtration

De-virus filtration

Chromatography

Liquid dispensing

Replenishment

Perfusion culture

Fluid delivery

Product Brochure

The newly developed K₂P series of intelligent pumps from HOLVES uses four-piston diaphragm pump as the power system, which has the characteristics of low shear and low pulsation. This series of intelligent pumps can greatly simplify the experimental and production process and improve work efficiency.