In modern industrial production, fermenters and bioreactors are two kinds of equipment that must be unfamiliar to everyone. But what are the differences and connections between the two? And how have they evolved over the course of history to meet the needs of advancing biotechnology?

Early fermenters were mostly simple ceramic containers; in the late 1800s and early 1900s, fermenters took shape and began to be made of metal (steel fermenters) and had simple temperature controllers; in the 1940s and 1960s, technologies such as mechanical agitation and ventilation, aseptic culture, etc., were gradually perfected, and not only did electrodes for pH and DO measurement appear, but computers were also available to control the process, which provided a boost to precise control of fermentation; from the 1980s to the present, the rapid development of modern industrial technology and biological science and technology has led to a rapid development in the appearance, materials and automation level of fermenters. From the 1980s to the present, the rapid development of modern industrial technology and biological science and technology has led to a rapid development in the appearance, materials and automation level of fermenters, and intelligent algorithms to optimize the control of the fermentation process and improve the yield. HOLVES Cla210 Laboratory Classic fermenter is an upgraded iteration of the La210 with intelligent automation.

In short, the fermenter from the initial ceramic material, to stainless steel, glass and other corrosion-resistant materials used, and then to the modern computer control system, the evolution of the fermenter witnessed the development of industrial biotechnology.

In the 1980s, the suspension culture technology of CHO cells was further developed and applied, and the rapid progress of therapeutic antibody production technology promoted the application of bioreactors in the field of biopharmaceuticals, and reached 10,000 scale-up industrialization at the end of the 1990s. During this period, the maturation of replenishment batch culture technology, perfusion culture technology, and genetic engineering technology greatly advanced the development of bioreactor technology into a versatile platform capable of being used for the production of a wide range of biologics such as viral vectors, live viruses, and virus-based vaccines.

In the 1980s, the suspension culture technology of CHO cells was further developed and applied, and the rapid progress of therapeutic antibody production technology promoted the application of bioreactors in the field of biopharmaceuticals, and reached 10,000 scale-up industrialization at the end of the 1990s. During this period, the maturation of replenishment batch culture technology, perfusion culture technology, and genetic engineering technology greatly advanced the development of bioreactor technology into a versatile platform capable of being used for the production of a wide range of biologics such as viral vectors, live viruses, and virus-based vaccines.

From the initial simple fermentation process to modern biotechnology fields such as genetic engineering and cell engineering, bioreactors have become indispensable tools. As biotechnology continues to advance, bioreactor design and functionality are being optimized to meet the need for greater efficiency and more precise control.

From the initial simple fermentation process to modern biotechnology fields such as genetic engineering and cell engineering, bioreactors have become indispensable tools. As biotechnology continues to advance, bioreactor design and functionality are being optimized to meet the need for greater efficiency and more precise control.

Fermenters and bioreactors are at the heart of industrial biotechnology, and their development not only reflects the pace of scientific and technological progress, but also heralds the infinite possibilities of the future bio-industry. With a deeper understanding of biological processes, we can expect these devices to play an even greater role in the future.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.

Definition and function of fermenters

Fermenter is a vessel used for fermentation process. It is not only a kind of bioreactor, but also the core equipment to realize the bioconversion process. Fermenters can be divided into various types according to their operation, structure and function, such as continuous, batch, stirred and so on. In industrial production, fermenters provide an ideal growth environment for microorganisms by controlling the temperature, pH, oxygen supply and other conditions, thus promoting the efficient production of target products.History of Fermenters

People actually discovered the phenomenon of fermentation early on, but it took hundreds of years to really understand it in depth. We've mentioned in previous articles that the history of microbial fermentation dates back to ancient times, but the development of the modern fermenter began in the early 1900s. Instead of simply fermenting for the purpose of obtaining food, modern fermentation has been given a different meaning.Early fermenters were mostly simple ceramic containers; in the late 1800s and early 1900s, fermenters took shape and began to be made of metal (steel fermenters) and had simple temperature controllers; in the 1940s and 1960s, technologies such as mechanical agitation and ventilation, aseptic culture, etc., were gradually perfected, and not only did electrodes for pH and DO measurement appear, but computers were also available to control the process, which provided a boost to precise control of fermentation; from the 1980s to the present, the rapid development of modern industrial technology and biological science and technology has led to a rapid development in the appearance, materials and automation level of fermenters. From the 1980s to the present, the rapid development of modern industrial technology and biological science and technology has led to a rapid development in the appearance, materials and automation level of fermenters, and intelligent algorithms to optimize the control of the fermentation process and improve the yield. HOLVES Cla210 Laboratory Classic fermenter is an upgraded iteration of the La210 with intelligent automation.

Definition of bioreactors

A bioreactor is a piece of equipment used for biological processes, which includes, but is not limited to, fermenters. Bioreactors can be categorized according to their purpose and mode of operation, such as for cell culture, enzyme reactions, tissue engineering, and so on. We have also explored these categories in more detail in the bioreactor series of articles.History and modern applications of bioreactors

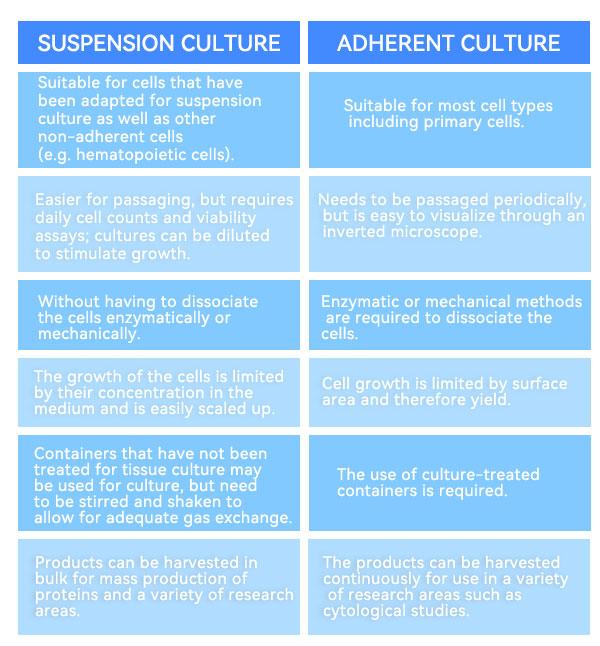

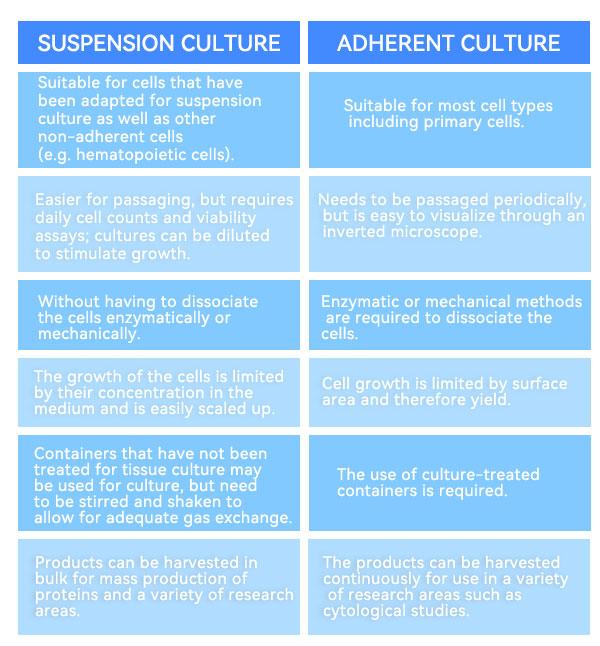

The development of bioreactors is closely related to that of fermenters, but with a much wider range of applications. Early devices were mainly for anaerobic microbial fermentation cultures, and after the 1940s, deep fermentations with aeration and stirring of liquids were gradually established.In 1962, Capstick and others made a breakthrough with the successful domestication and suspension culture of BHK21 cells, which paved the way for the large-scale production of veterinary vaccines.In 1967, VanWezel also developed micro carriers and realized large-scale culture of adherent cells in bioreactors.

Fermenters and bioreactors are at the heart of industrial biotechnology, and their development not only reflects the pace of scientific and technological progress, but also heralds the infinite possibilities of the future bio-industry. With a deeper understanding of biological processes, we can expect these devices to play an even greater role in the future.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.