TFF Systems

-

HOLVES is focused on tangential flow ultrafiltration solutions, providing advanced and reliable sanitary ultrafiltration systems for pharmaceutical grade applications, with a focus on the development and production of automated systems. Through years of development, HOLVES has been able to provide users from small-scale automated ultrafiltration systems for research to fully automated and intelligent tangential flow ultrafiltration systems for large-scale production, which are widely used in advanced pharmaceutical sciences such as biopharmaceuticals, synthetic biology and chemical pharmaceuticals.

-

HOLVES maintains close cooperation with PALL and Millipore to continuously introduce adapted and alternative systems to meet market demands. At the same time, Halls is committed to innovation in product design and has successfully introduced the SlessW seamless welding technology, which removes as much dead space as possible from the weld and improves the cleanliness and safety of the system. In terms of automation systems, Halls has adopted the new generation of Industry 4.0 IoT technology to ensure that our ultrafiltration systems are able to adapt to the future trend of fully automated production, and continue to provide efficient and reliable service to our customers.

Membrane Holding Fixture

HOLVES designs and manufactures the industry's top membrane holding fixtures, which benchmark and exceed imported membrane holding fixtures. HOLVES Membrane Holding Fixtures are made of sanitary AISI 316L stainless steel, and the internal and external surfaces are machined with high precision and polished with a complex polishing process, which consists of six fine machining procedures. The high standard manufacturing process ensures that the surface finish of the fixture, Ra ≤ 0.2um surface roughness index is far lower than the general industrial standards, to meet the very high requirements for product surface quality applications.

The whole fixture is generated and verified by the original 3D design to ensure that it is suitable for all kinds of imported brand film packages.

- Adaptability: Provide Millipore, PALL, Sartorius and other imported brands of adaptive fixtures.

- Wide range of sizes: From small 0.1㎡ to production 14㎡ membrane holding fixtures to meet the needs of different sizes of applications.

- Various products: Provide four-dimensional screw-fixed manual version and hydraulic auto-locking production-type membrane holding fixtures to meet the user's different operational needs.

- Customization service: The fixtures can be customized from R&D to production specifications to meet the needs of a wide range of applications.

SlessWSeamless Welding Technology

Due to the bending and dead-end problems of the pipe, the traditional pipe welding quality is still difficult to reach the high standard of no depression and no dead space, and the weld seam still has the risk of rust after acid or alkali washing treatment. Therefore, converging to the welding requirements of finished sanitary pipe application, HOLVES supply chain and the R&D team have finally broken through the limitations of the traditional welding technology after 9 months of unremitting efforts and dozens of trial and error solutions, and launched the revolutionary SlessW seamless welding technology.

- Sanitary standard: The welded pipe is close to the finished sanitary pipe standard.

- Wide applicability: It is also suitable for most welding scenarios, including flat joints, right-angle bends, non-right-angle bends and other complex scenarios.

- Eliminating Dead Space: Technology Eliminates Dead Space Problems in Conventional Welding.

- Anti-corrosion and anti-pollution: Reduces rust and welding slag, theoretically ensures pure fluid in the pipeline and reduces the risk of equipment contamination.

Boxed Flat Film Package

PALL and Millipore, as industry pioneers in tangential flow ultrafiltration technology, have always provided high quality filtration solutions and related consumables. Halls always maintains close cooperation with PALL and Millipore to continuously introduce more suitable solutions and systems. At the same time, providing original imported membrane packages from PALL and Millipore, and highly adapted to the core original design and data, HOLVES TFF systems provide users with a comprehensive, demanding, and cost-effective solution in the overall solution.

HOLVES uses the new generation of PALL and Millipore original boxed flat film packages, including but not limited to:

- 0.1㎡ / 0.5㎡ / 2.5㎡

- Second generation film package, third generation film package

- PES(polyethersulfone), RC(regenerated cellulose), and PVDF(polyvinylidene fluoride) are available.

- A variety of specifications mesh, adapted to the concentration and separation of different concentrations or viscosity solutions.

| MODEL | MWCO (KD) | IDEAL MWCO>99% (KD) |

| PES-5 | 5 | 12-25 (Growth factors, Hormone) |

| PES-8 | 8 | 25-50 (Growth factors, Hormone) |

| PES-10 | 10 | 50-100 (Growth factors, Hormone) |

| PES-30 | 30 | 100-140 (Enzyme) |

| PES-50 | 50 | 140-300 (IgGs) |

| PES-100 | 100 | 300-500 (Parvovirus, Antigen) |

| PES-300 | 300 | >500 (IgMs, Virus) |

| PES-500 | 500 | >0.3μm (Colloid, Particle) |

| PES-1000 | 1000 | >0.3μm (Colloid, Particle) |

| RC-5 | 5 | 8-18 (Proinsulin, Hemopoietic factor) |

| RC-10 | 10 | 18-60 (Hemoglobin, Enzyme) |

| RC-30 | 30 | 60-200 (Monoclonal antibody(mAb)) |

| RC-100 | 100 | 200-500 (Parvovirus, Virus antigen) |

| RC-300 | 300 | >500 (IgMs, Virus) |

| RC-1000 | 500 | >0.3μm (Colloid, Particle) |

| PVDF (Microfiltration) | 0.1μm / 0.22μm / 0.45μm / 0.65μm | Bacteria with large diameter, Particle |

K₂T-Control Ultrafiltration Control System

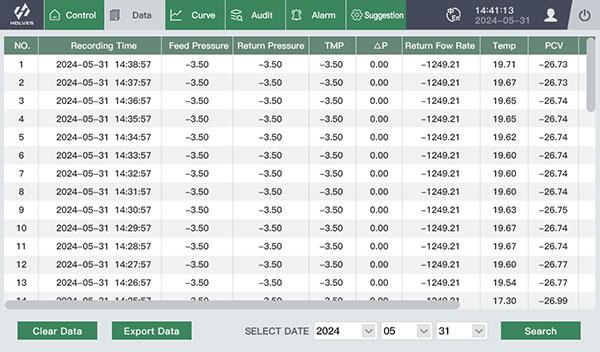

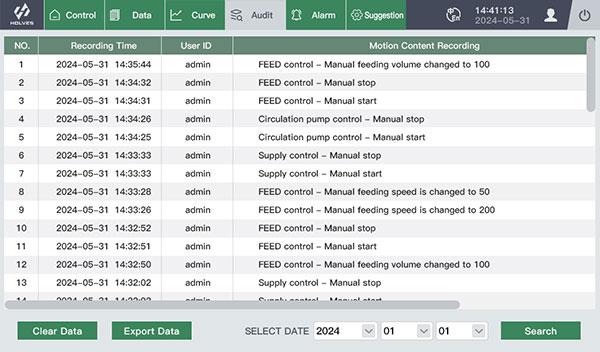

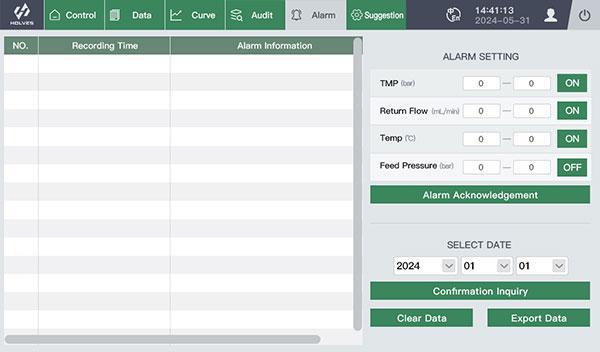

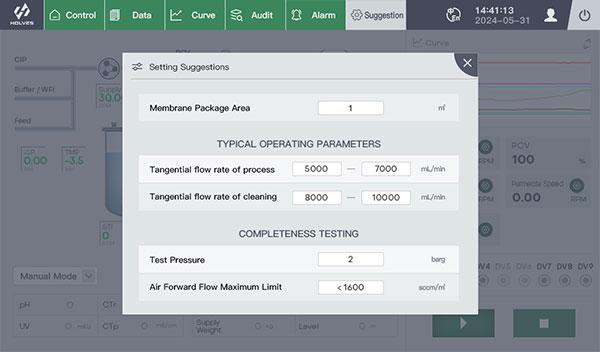

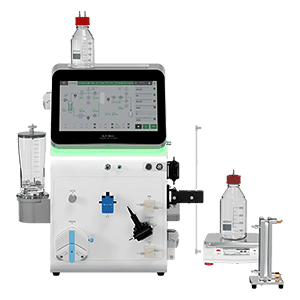

The HMI interface design of the HOLVES TFF system provides an excellent operating experience with its efficient, intuitive and intelligent features. This design not only improves ease of operation and system reliability, but also ensures compatibility with future trends in automated production by integrating the latest Industry 4.0 IoT technology.

- Intuitive User Interface: Making it possible for the user to quickly identify problems and adjust the operation in time to optimize the production process.

- Convenient Operation Process: To realize automatic concentration and dialysis, and preset concentration, filter washing and other process procedures.

- Intelligent Monitor and Control: Online monitoring and control of various parameters.

- Automation and IoT Technology: HOLVES has adopted the new generation of Industry 4.0 IoT technology.

- Remote Access and After-sales Support: The HMI interface allows remote access, users can monitor and control the process remotely.

Discover Our Products

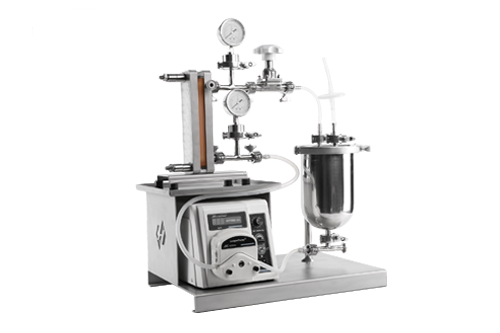

K₂T-Mini

Tangential Flow Ultrafiltration System

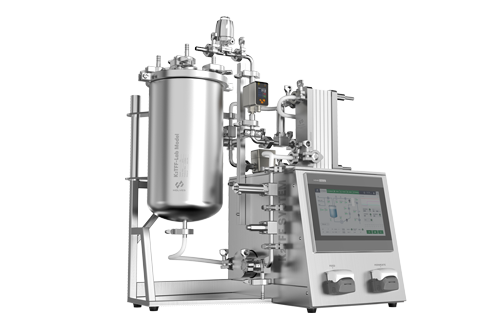

K₂T-Lab

Manual Tangential Flow UF System

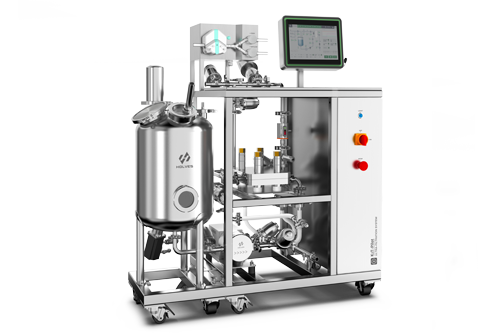

K₂T-Lab Pro

Automatic Tangential Flow UF System

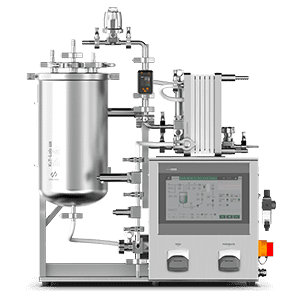

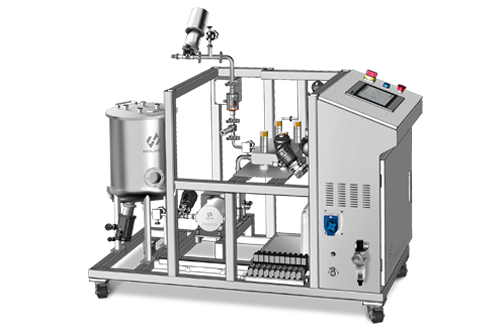

K₂T-Pilot

Automatic Ultrafiltration System

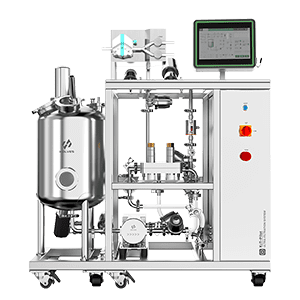

K₂T-Produt

Automatic Ultrafiltration System

Product Applications

Product Brochure

HOLVES offers advanced pharmaceutical grade tangential flow ultrafiltration systems and is dedicated to the development and production of automated systems. The product line ranges from small scale research to large scale production automation systems for a wide range of applications in biopharmaceuticals, synthetic biology and chemical pharmaceuticals.