In nature, the evaporation of water is a magical process, this natural phenomenon is endowed with the wisdom of industry, capture the moment of water molecules rise, the use of technology to convert liquid substances into dry powder. Small spray dryer is the bridge in nature and industry, this article will take a comprehensive and in-depth perspective, take you to explore and discover together.

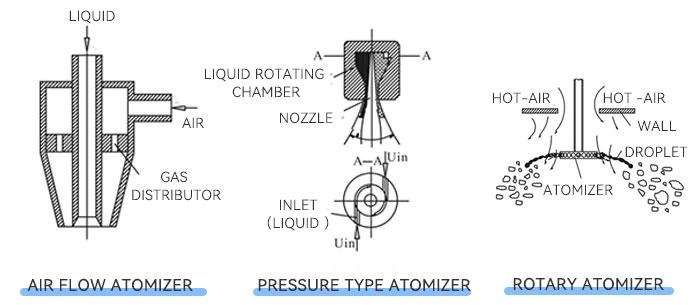

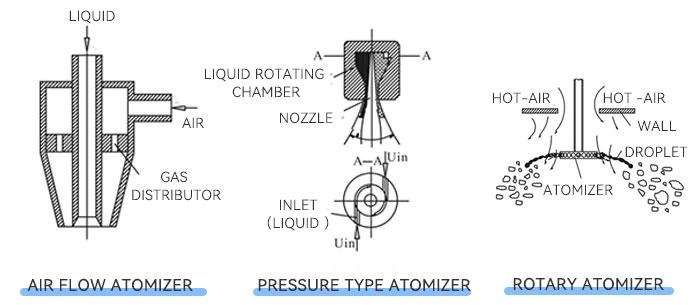

1. Centrifugal atomizer: using high-speed rotation to generate shear force, the liquid will be dispersed into fine droplets. It is characterized by simple structure and easy maintenance, but the atomization effect is greatly affected by the viscosity of the liquid.

2. Pressure type atomizer: The liquid is delivered to the nozzle through a high-pressure pump to form fog droplets. This type of atomizer is suitable for high viscosity liquids, but requires high pressure stability of the pump.

3. Airflow atomizer: the use of compressed air at high speed from the nozzle spray, and with another channel conveying the material mixture, with the relative speed between the gas-liquid phase of the friction generated by the difference between the two phases of the liquid, so that the material is split into droplets.

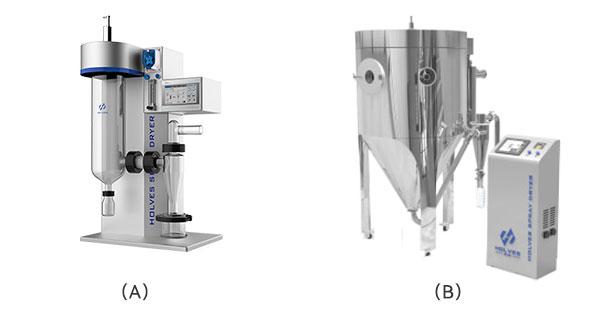

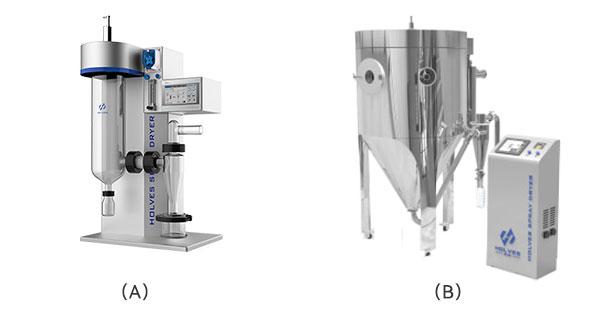

The small spray drying H-Spray Mini from HOLVES uses a two-fluid atomizer, which is not only simple and easy to operate for a wide range of applications, but also sprays dry particles that are very fine and homogeneous.

1. Electric heating: through the electric energy to produce heat, dry materials. Simple operation, easy to control, but the thermal efficiency is relatively low.

2. Steam heating: steam heating is a more common heating method, through the introduction of steam to heating. This way of high thermal efficiency, suitable for large-scale production, but requires a stable supply of steam.

1. Shape and size: choose the appropriate shape and size of the drying chamber according to the production requirements to ensure that the droplets are uniformly distributed in the drying chamber.

2. Airflow organization: Reasonable design of airflow path to achieve effective contact between hot air and droplets and improve drying efficiency.

3. Material selection: the internal material of the drying chamber should have good corrosion resistance and high temperature resistance to adapt to different drying environments, the common ones are stainless steel drying tower, Plexiglas drying tower and so on.

1. Intelligent monitoring: HOLVES control system monitors the parameters in the drying process in real time by means of advanced sensors and monitoring equipment to ensure the stability of the whole drying process.

2. Automatic adjustment: The system can automatically adjust the working status of the equipment according to the real-time data, for example, after starting the system, the intelligent PID temperature system will be automatically heated and adjusted to the set temperature and so on.

3. Data recording and analysis: HOLVES control system HS-Control V2.0 is equipped with powerful data recording and alarm functions, which can record all the key data in the drying process and carry out in-depth analysis to provide a basis for optimizing the production process.

1. Viscosity: different viscosity of the material on the atomization effect and drying rate has a significant impact on the need to choose the appropriate atomizer and process parameters.

2. Heat sensitivity: for heat-sensitive materials, the temperature in the drying process needs to be controlled to prevent material denaturation or degradation.

3. Particle: the particle size, shape and density of the material and other characteristics, will also affect the quality of the dried product.

With the continuous evolution of modern technology, small spray dryer shows unlimited potential in improving production efficiency, optimizing energy use and ensuring product quality. At the same time its advantages also play an important role in many fields. After that, we will continue to explore the technical innovation and application expansion of small spray dryer. Through continuous research and practice, we expect that this technology can make a greater contribution to promoting the green transformation and sustainable development of industrial production.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.

Key components of a small spray dryer

- Atomizers

2. Pressure type atomizer: The liquid is delivered to the nozzle through a high-pressure pump to form fog droplets. This type of atomizer is suitable for high viscosity liquids, but requires high pressure stability of the pump.

3. Airflow atomizer: the use of compressed air at high speed from the nozzle spray, and with another channel conveying the material mixture, with the relative speed between the gas-liquid phase of the friction generated by the difference between the two phases of the liquid, so that the material is split into droplets.

The small spray drying H-Spray Mini from HOLVES uses a two-fluid atomizer, which is not only simple and easy to operate for a wide range of applications, but also sprays dry particles that are very fine and homogeneous.

- Heat source systems

1. Electric heating: through the electric energy to produce heat, dry materials. Simple operation, easy to control, but the thermal efficiency is relatively low.

2. Steam heating: steam heating is a more common heating method, through the introduction of steam to heating. This way of high thermal efficiency, suitable for large-scale production, but requires a stable supply of steam.

- Design of drying towers

1. Shape and size: choose the appropriate shape and size of the drying chamber according to the production requirements to ensure that the droplets are uniformly distributed in the drying chamber.

2. Airflow organization: Reasonable design of airflow path to achieve effective contact between hot air and droplets and improve drying efficiency.

3. Material selection: the internal material of the drying chamber should have good corrosion resistance and high temperature resistance to adapt to different drying environments, the common ones are stainless steel drying tower, Plexiglas drying tower and so on.

Intelligent small spray dryer

Among the many components of a small spray dryer, the control system plays a crucial role. The control system HS-Control V2.0 of HOLVES small spray dryer provides a strong guarantee for the whole drying process with its intelligence and precision.

2. Automatic adjustment: The system can automatically adjust the working status of the equipment according to the real-time data, for example, after starting the system, the intelligent PID temperature system will be automatically heated and adjusted to the set temperature and so on.

3. Data recording and analysis: HOLVES control system HS-Control V2.0 is equipped with powerful data recording and alarm functions, which can record all the key data in the drying process and carry out in-depth analysis to provide a basis for optimizing the production process.

Material and Adaptability Analysis

The characteristics of the material will affect the efficiency of the small spray dryer and product quality, in-depth analysis of the material characteristics, including:1. Viscosity: different viscosity of the material on the atomization effect and drying rate has a significant impact on the need to choose the appropriate atomizer and process parameters.

2. Heat sensitivity: for heat-sensitive materials, the temperature in the drying process needs to be controlled to prevent material denaturation or degradation.

3. Particle: the particle size, shape and density of the material and other characteristics, will also affect the quality of the dried product.

With the continuous evolution of modern technology, small spray dryer shows unlimited potential in improving production efficiency, optimizing energy use and ensuring product quality. At the same time its advantages also play an important role in many fields. After that, we will continue to explore the technical innovation and application expansion of small spray dryer. Through continuous research and practice, we expect that this technology can make a greater contribution to promoting the green transformation and sustainable development of industrial production.

Here is the Holves brand website, https://www.bjholves.com/. Providing different types of industry information, technical knowledge, and solutions, we have developed and produced several new laboratory fermenter, bioreactor, tangential flow filtration system and other equipment to meet your needs from experimental to industrial production.